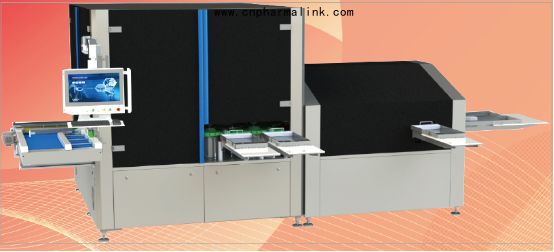

Equipment overview

The machine vision principle is used to identify and detect the visible foreign matters and defects. During the inner liquid inspection, the inspected product is braked to a standstill during high-speed rotation, and the industrial camera continuously takes pictures to obtain multiple images, which are processed by the visual inspection algorithm independently developed by our company to judge whether the inspected product is qualified; During the appearance inspection, takes pictures of 360 degree without blind spots, after visual algorithm processing, the appearance defects are identified. When detecting micro-hole leakage, it is detected by the principle of high-voltage discharge. All the test results are communicated to the PLC control system via Ethernet, and configured according to the type of rejection channel to realize automatic rejection of unqualified products.

Product features

Online or offline detection, automatic feeding, automatic detection, and automatic rejection of unqualified products.

There are many unqualified product channels, and the rejection types can be configured.

The whole detection process can be traced, and the data is automatically stored.

The overall equipment design and manufacturing comply with GMP and GAMP standards.

Waterproof structure design is adopted partly, which is convenient for cleaning broken bottle. The broken bottle area can be directly washed with water.

Technical parameters

|

Equipment model |

HR-KA80T/H-400b |

HR-KA80T/H-600b |

|

Application |

2ml-20ml 2ml-20ml bottle type |

|

|

Inspection items |

Foreign matters in the liquid, bottle body defects (cracks, black spots), bottle cap defects (flanging, crooked caps, incomplete aluminum caps, etc.), liquid volume, micro-hole leakage |

|

|

Voltage |

AC 380V, 50Hz |

|

|

Power |

16KW |

|

|

Compressed air consumption |

0.5-0.7Mpa, 0.2m³/min |

|

|

Max production capacity |

24,000pcs/h |

36,000pcs/h |