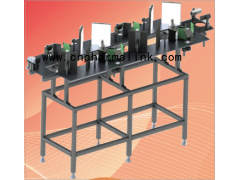

Automatic intelligent inspection machine for empty bottle defects (plastic bottle/soft PP bottle/glass bottle)

Equipment overview

The quality inspection of the empty bottle after blowing and before filling is carried out. The equipment is installed on the clamping chain after bottle blowing. The bottle passes through the sensor, highlights the defects under the special light source, triggers the high-speed camera to take pictures, and then processes it through the image analysis system to achieve the purpose of detection.

Product features

It occupies a small area, so there is no need to change the existing production line, which does not affect the normal production.

The function is modular, and the station can be selected according to the on-site environment.

The software has a complete traceability function, which can completely store the inspection records, alarm records and operation records and query them at any time.

The software has defect learning ability and supports the optimization of detection performance.

Support recipe management and adjustable detection parameters.

Compatible with a variety of bottle specifications, easy to change specifications.

The equipment has sound and light alarms under abnormal conditions, and displays alarm information and processing suggestions.

Technical parameters

|

Equipment model |

HR-KP300 |

HR-KP400 |

|

Application |

50-500ml |

|

|

Inspection items |

Inspection items such as no hanger ring, crooked hanger ring, bottle bottom accumulation material, bottom groove, bottle body black spots, bottle body bubbles and irregular bottles, etc. |

|

|

Voltage |

AC 220V, 50Hz |

|

|

Power |

1.5KW |

|

|

Compressed air consumption |

0.6MPa, 0.1m³/min |

|

|

Max production capacity |

18000pcs/h |

24000pcs/h |