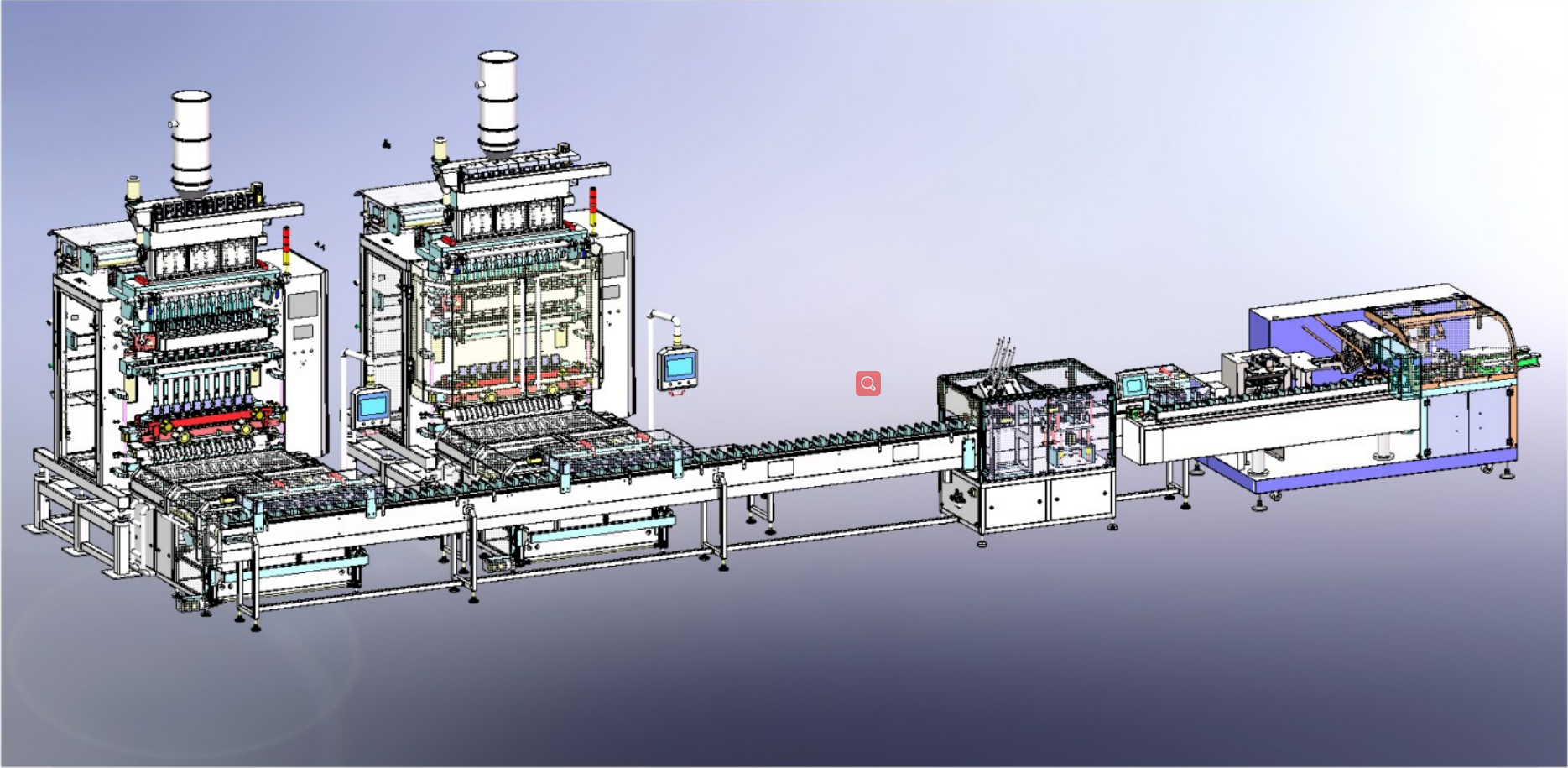

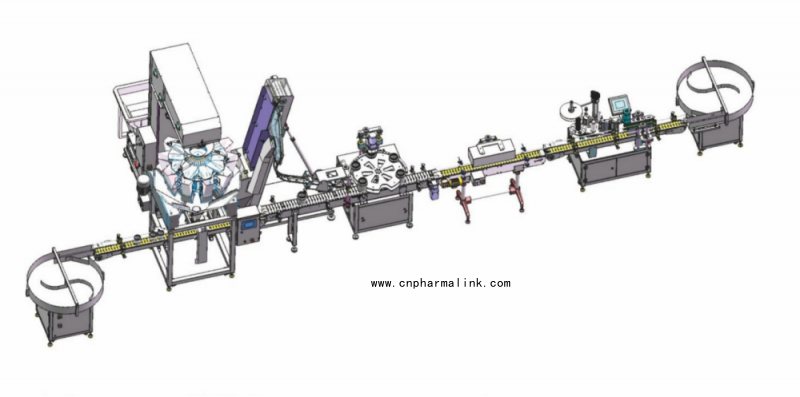

This automatic production line is used for screw capping type aluminum foil sealing round bottle product

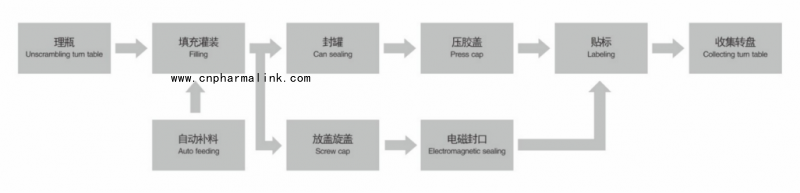

Bottle line process:

Advantage:

1.High automation,one-button start,easy operation.

2.More reflect the enterprise customization,meet different product or bottle specifation as required,or freely assemble the equipments to make required production line.

3.Electronic scale weighing,high accuracy filling,with product unqualified removed function.

4.Auger filling with dust collection device,no powder flying when in prodction, make sure the bottle cleaning and good sealing.

5.Label machine can be equipped with thermal transfer printer,edit the print

contect at will.

|

Automatic filling line for TCM drinks |

|

|

Equipment name |

Parameter |

|

Turn table |

1.Suitable bottle:round bottle |

|

2.Driving way:by motor |

|

|

3.Turn table dia:1200mm |

|

|

4.Bottle specification: Φ50-100mm |

|

|

5.Unscramble bottle speed:20-50 bottles/min |

|

|

Linear type small 10 heads weigher filling machine |

1.Weighing way:small 10 heads weigher |

|

2.Heads quantity:10 heads |

|

|

3.Bucket volume:0.5L |

|

|

4.Weighing range:5-200g |

|

|

5.Weighing arruracy:±0.3-1.5g(depends on material) |

|

|

6.Filling speed:15-30 bottles/min |

|

|

7.Conveying way:by chain-plate |

|

|

8.Driving way:converter motor |

|

|

Linear type auqer filling Machine |

1.Filling way:CCL-3L Auger screw filler |

|

2.Filling range:15-300ml(depends on material,one set screw included) |

|

|

3.Filling accuracy:±5%(depends on material) |

|

|

4.Filling speed:15.30 bottles/min |

|

|

5.Convevinq way:by chian-plate |

|

|

6.Driving way:converter mator |

|

|

Z shape bucket elevator (with vibration feeder) |

1.Conveying product:Granule(like herbal pieces, candy,biscuit etc.) |

|

2.Hopper material:1.8L food grade plastic hopper |

|

|

3.Discharge heigheL2.6m(according to final design drawing) |

|

|

4.Conveying capacity∶3-5m³/h |

|

|

5.Frame,chain,chain wheel are 304SS,independent electric cabinet,with manual and auto function |

|

|

Vacuum feeding machine (without feeding bucket) |

1.Model:QVC-3 Vacuum feeding machine |

|

2.Vacuum generator:model QV300 |

|

|

3.Filter:model 50*200 |

|

|

4.Conveying capacity:150-600kg/h |

|

|

5.Suction hose:food grade steel wire plastic pipe |

|

|

6.Stainless steel suction pipe:304SS |

|

|

7.Material of Ψ290 lid,bucket body,filter:304SS |

|

|

Automatic rotating type botte sealing machine |

1.Model:FG100A |

|

2.Material:Stainless steel |

|

|

3.Sealing head quantity:1 |

|

|

4.Sealing speed:30pcs/min |

|

|

5.Sealing height:50-200mm |

|

|

6.Suitable for bottle diameter:35-100mm |

|

|

Automatic round bottle labeling machine |

1.Labeling sccuracy:±0.5mm(not including product, label rror) |

|

2.Labeling speed:15-25 pcs/min(related to product sizs and operator skilled) |

|

|

3.Suitable for product diameter(for round bottle):Φ15 mm-150mm; height:250mm |

|

|

4.Suitable for label size:L:20mm-220mm;W(bottomwidth):20mm-220mm |

|

|

Collecting turn table |

1.Suitable bottle:Round bottle |

|

2.Driving way: by motor |

|

|

3.Turn table diameter:1200mm |

|

|

4.Bottle specification:Φ50-100mm |

|

|

5.Unscrambling speed:20-50 bottles/min |

|