Approximate price:negotiate

Minimum order quantity:1 set

Delivery time:negotiate

Terms of transaction:FOB

Payment terms:T/T

Product Introduction:below

Product features:below

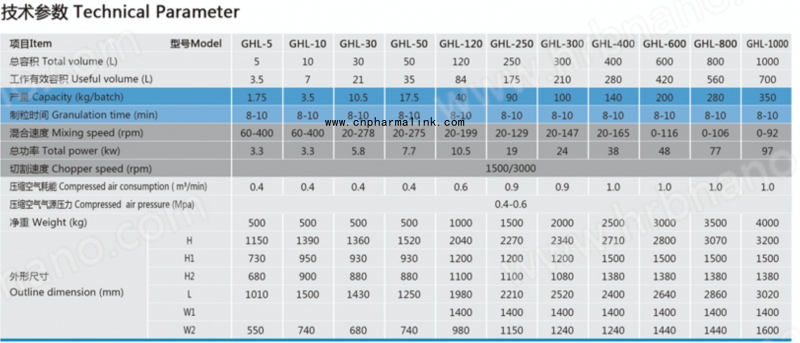

Technical parameters:The attachment picture

Application: below

The main products1.MODEL GHL HIGH SHEAR GRANULATOR

Application

This equipment is used for making wet granules in the solid dosage production procedure. It is also widely used in pharmaceutical, foodstuff and chemical industries.

Working Principle

In wet granulation, powder is charged into the working vessel and the product is vigorously mixed by an impeller. Then it is wetted by spraying binder. Finally it becomes uniform wet granules by a chopper

Features

Reversed taper granulating bowl design, special shaped

■ Reversed taper granulating bowl design, special shaped

impeller and chopper to ensure uniform final products.

■ Granulating process is completed in a closed bowl system,

dust free and complying with cGMP requirements.

■ Easy and safe operation, achieve mixing and granulating

in one process.

■ HMI and PLC control system, motor speed is controlled by

VFD, and all process parameters can be recorded.

■ Compressed air and water can be alternatively connected

to the machine so as to ensure quick and efficient washing.

Options

■ Product charging by lifting machine

■ Product charging by vacuum transfer system

■ Jacket bowl wall design for heating or cooling

■ Wet mill or oscillating granulator

■ Automatic binder solution spraying system

■ Printer

■ WIP system

■ Explosion proof design