Approximate price:negotiate

Minimum order quantity:1 set

Delivery time:negotiate

Terms of transaction:FOB

Payment terms:T/T

Product Introduction:below

Product features:below

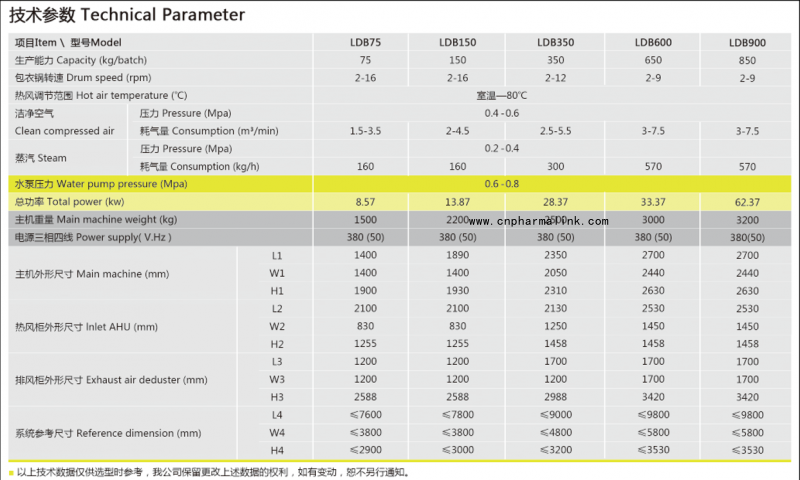

Technical parameters:The attachment picture

Application: below

MODEL LDB COATING MACHINE

Application

coating machine is widely used in the pharmaceutical and foodstuffs industries for the organic, water-soluble film and sugar coating of tablets, pills and sweets. It can achieve medicine delayed release. It is easy to operate.

Features

■ The increased drum length of this machine makes it possible to process large batch size of products. Coating capacity is two times of traditional coating machine.

■ Patented guiding plate adopts double helix structure. Along with the rotation of drum, the tablets in the drum achieve 3-D movement. As a result, product bed is mixed homogeneously and coating quality is improved.

■ Coating time is shortened due to specially designed heat exchange system. Transfer of hot air is completed inside of tablet cores, no influence on atomization angle of spraying, so coating medium is saved.

■ Unique impeller design realizes positive rotation for coating operation and negative rotation for products discharging.

■ CIP cleaning system guarantees efficient cleaning and validation after each batch.

■ The spray system adopts the most advanced imported spray gun and the spraying process becomes more reliable and stable.

■ Sensors for detecting negative pressure, humidity and product temperature are equipped. Air flap, air volume and steam close/open are adjusted automatically via PLC, realizing automatic process control.

Working Principle

This machine adopts double helix principle to realize homogeneous mixing of tablets. The reciprocating movement of tablets in the drum and rolling movement along with the rotation of drum make the tablets realize 3-D movement. As a result, surface flatness and smoothness of tablets are improved and good coating quality is achieved.