Pharmaceutical and medical equipment tank integrated cip sip Reactor Blending Production Mixer

Overview/Quick Details

You may also like

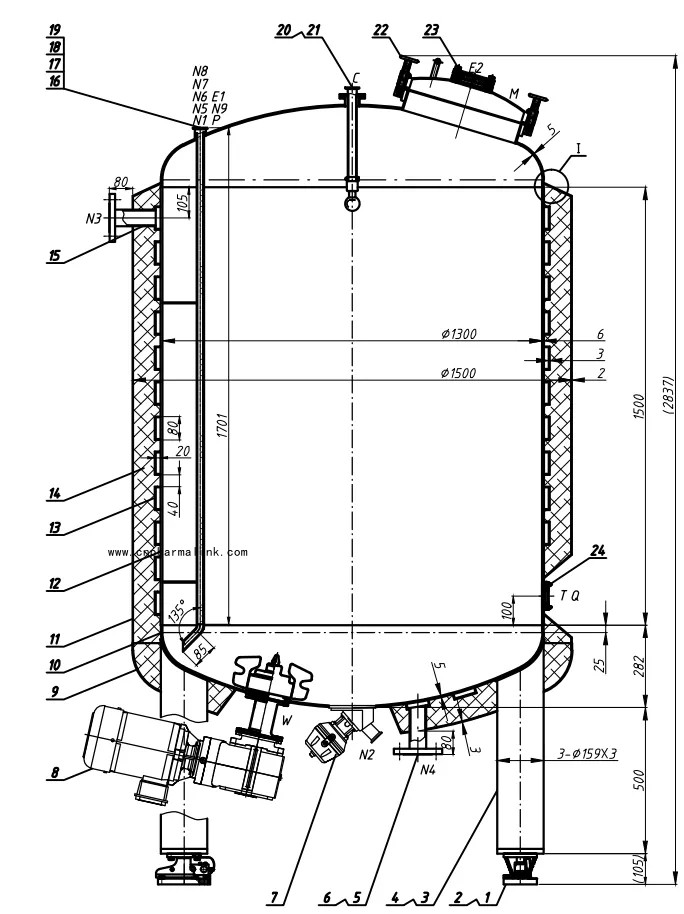

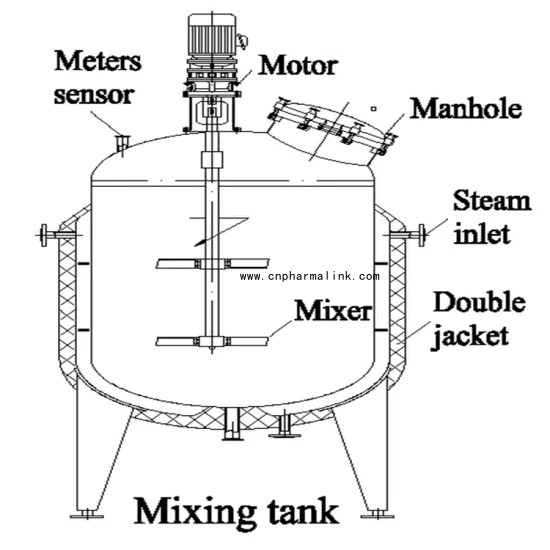

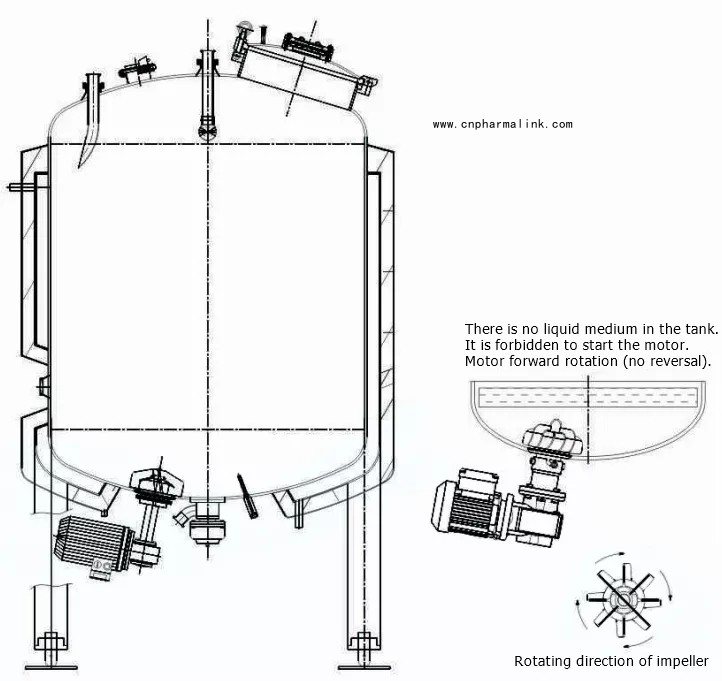

Product Paramenters

Details technical

1.Capacity:50L-50000L

2.Materical:SS304 /SS2507/SS2205/SS316

3.Single layer/Double layers/Three layers

4.Polished inside and outside

5.Quick open manhole

Frequently bought together

Supplier's popular products

KEAN is a highly professional manufacturing entity focusing on fabricating pressure vessel and tanks, integrated bioengineering

fermentation systems, cell culture systems, large infusion systems, fluid handling system, CIP/SIP systems.

2. Can you product as specific size?

Definitely we can. Our products are customized as per your requirements.

3. Can I have samples to test?

Yes, we are pleased to supply samples test report issued by renowned authority and ensure quality. Our products are fabricated

stringently in compliant with ISO, ASME BPE, cGMP international codes.

4. Do you have any MQQ limitation?

Our MQQ is 1 PC to supply new customers.

5. How long is the lead time?

Normally it takes 5-6 weeks for stainless steel tank, 7-10 weeks for integrate modular systems.

6. Do you provide after-sales service?

Yes, we are committed to offering highly professional and real-time after-sales service. We have many professional and dedicated

engineers available ensuring a holistic service to our highly-respected customers.

Contact us, let's discuss more!

Overview/Quick Details

| Place of Origin: | Hebei, China | Warranty: | 1 Year |

| Brand Name: | KEAN | Key Selling Points: | Easy to Operate |

| Condition: | New | Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Energy & Mining, Pharmaceutical food daily chemical electronics |

| Video outgoing-inspection: | Provided | Showroom Location: | Saudi Arabia, Pakistan, Kenya, Argentina, Romania |

| Machinery Test Report: | Provided | Material: | Stainleee Steel 301/316L/2507/2205 |

| Marketing Type: | New Product 2020 | Working pressure: | 0.1-1.0MPA |

| Warranty of core components: | 1 Year | Certification: | ISO9001 ASME |

| Core Components: | Motor, Pressure vessel | Key words: | Stainless Steel Pressure Tank |

| Dimension(L*W*H): | CUSTOMIZation | Function: | Mixed dispersive emulsification homogeneous |

| Capacity: | 50L-50000L | Standard: | GB ASME EN |

| Weight: | 5KG-5tons | MOQ: | 1SET |

| Volume (m³): | 50L-50000L | Application: | Pharmaceutical food daily chemical electronics |

| Inner Material: | stainless steel | Package: | Wooden Box |

| Outer Material: | stainless steel | Type: | Vertical horizontal |

| Design Pressure(MPa): | 1.0 mpa | After-sales Service Provided: | Free spare parts, Field installation, commissioning and training, Online support |

| Max Working Pressure(MPa): | 1.0 MPa | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Design Standard: | ASME-BPE | Local Service Location: | France, Pakistan, India, Morocco, Sri Lanka, Romania |

| Working Temperature(℃): | -30 - 300 ℃ | ||

| Supply Ability | |||

| Supply Ability | 50000 Piece/Pieces per Year | ||

| Packaging & Delivery | |||

| Packaging Details | woods packing | ||

| Port | qingdao.tianjin |

You may also like

Product Paramenters

Details technical

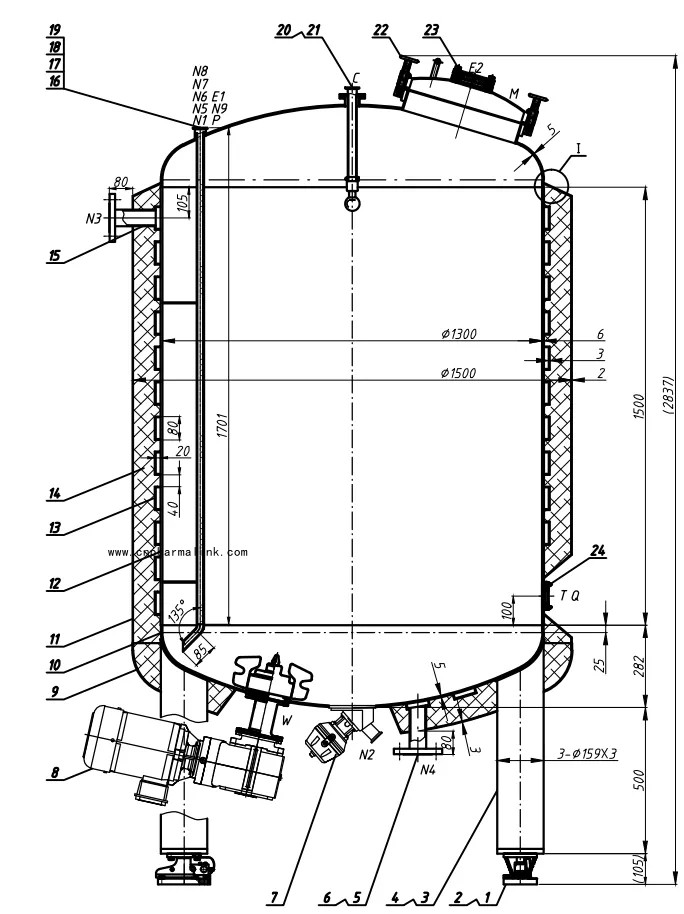

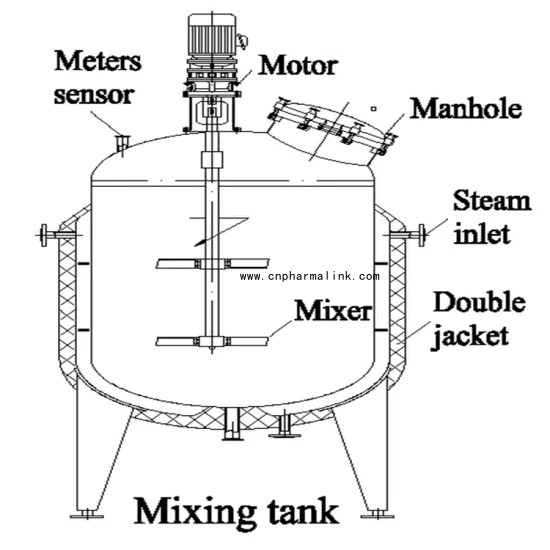

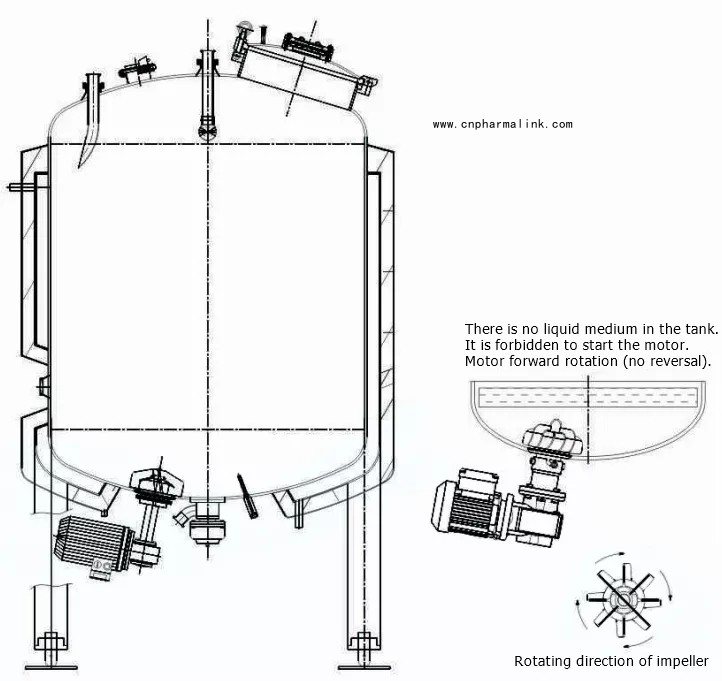

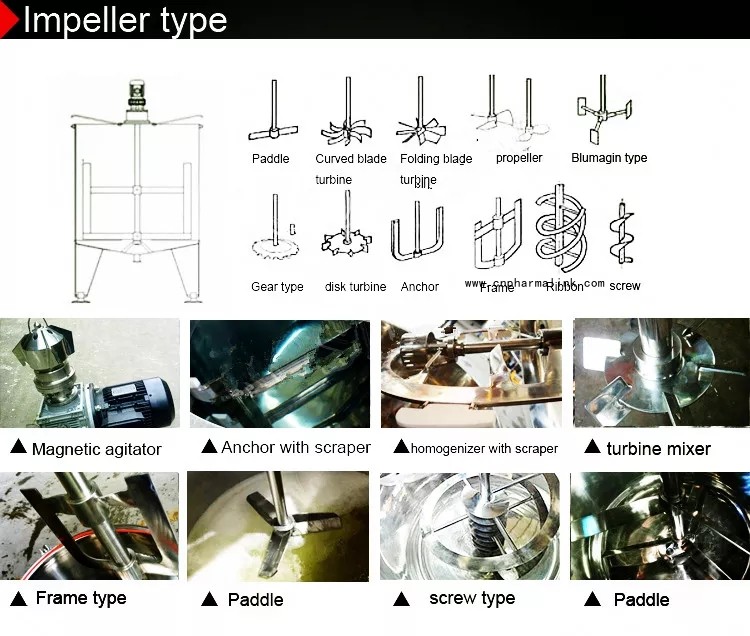

Specification:

1.Capacity:50L-50000L

2.Materical:SS304 /SS2507/SS2205/SS316

3.Single layer/Double layers/Three layers

4.Polished inside and outside

5.Quick open manhole

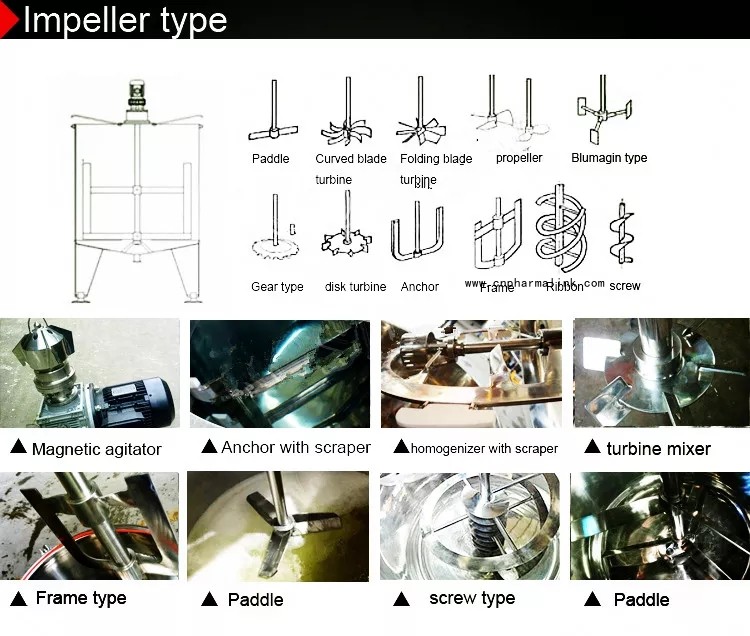

6.Agitator Power:0.25-15KW

Frequently bought together

Supplier's popular products

FAQ

1. Is your company a factory or trading company?

KEAN is a highly professional manufacturing entity focusing on fabricating pressure vessel and tanks, integrated bioengineering

fermentation systems, cell culture systems, large infusion systems, fluid handling system, CIP/SIP systems.

2. Can you product as specific size?

Definitely we can. Our products are customized as per your requirements.

3. Can I have samples to test?

Yes, we are pleased to supply samples test report issued by renowned authority and ensure quality. Our products are fabricated

stringently in compliant with ISO, ASME BPE, cGMP international codes.

4. Do you have any MQQ limitation?

Our MQQ is 1 PC to supply new customers.

5. How long is the lead time?

Normally it takes 5-6 weeks for stainless steel tank, 7-10 weeks for integrate modular systems.

6. Do you provide after-sales service?

Yes, we are committed to offering highly professional and real-time after-sales service. We have many professional and dedicated

engineers available ensuring a holistic service to our highly-respected customers.

Contact us, let's discuss more!