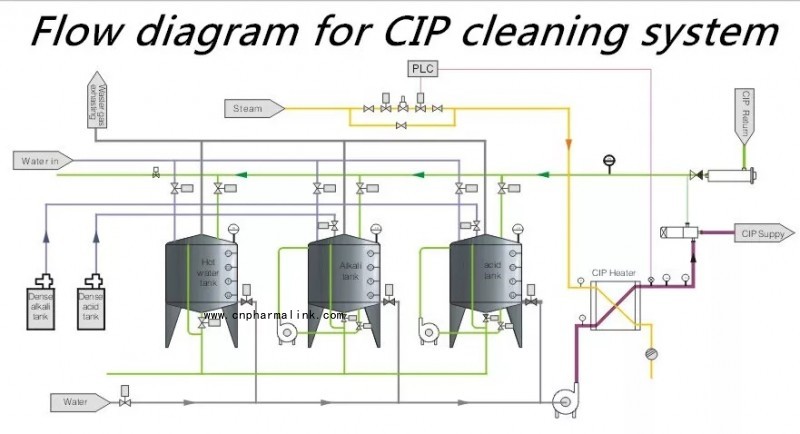

tank integrated cipsip system small portable cip cleaning system

Overview/Quick Details

Product Description

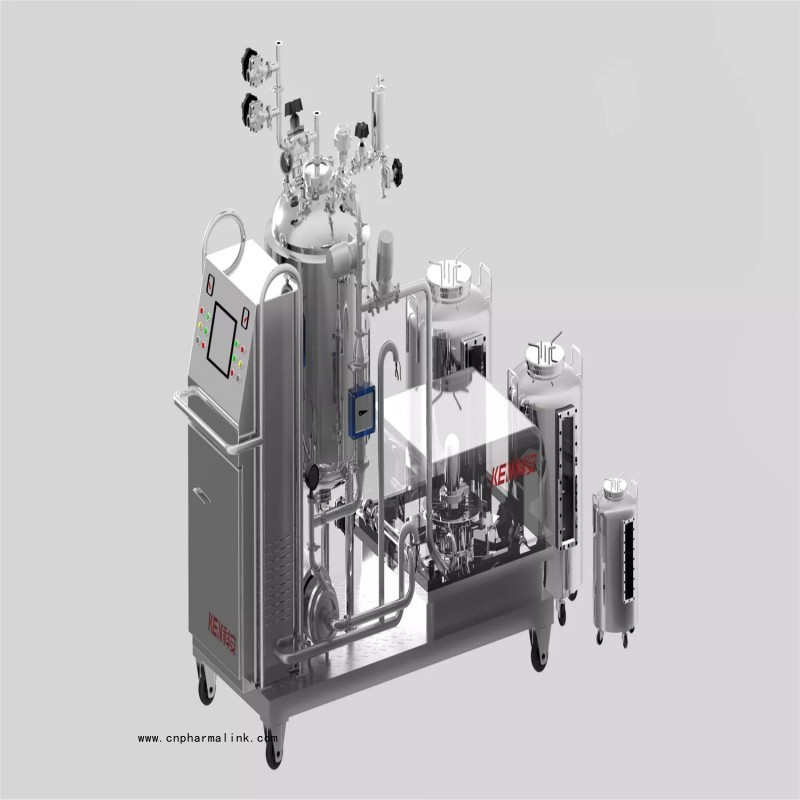

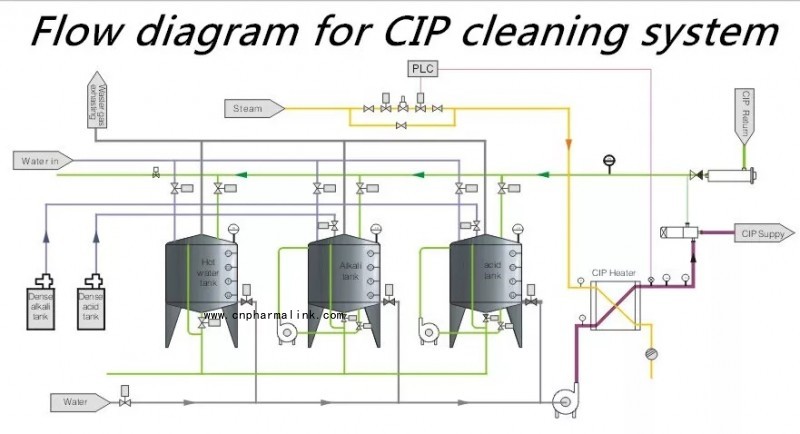

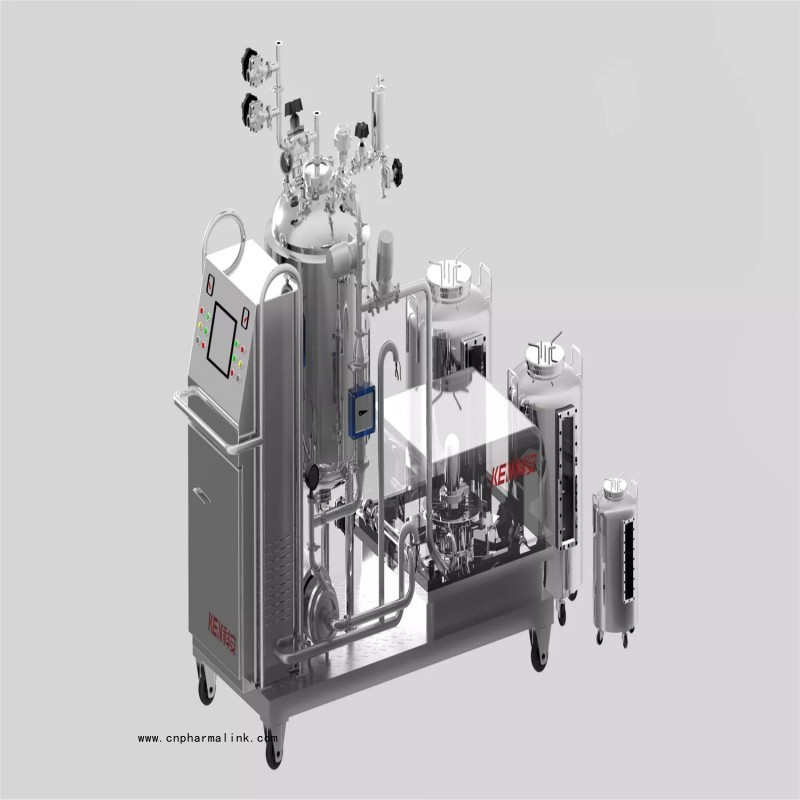

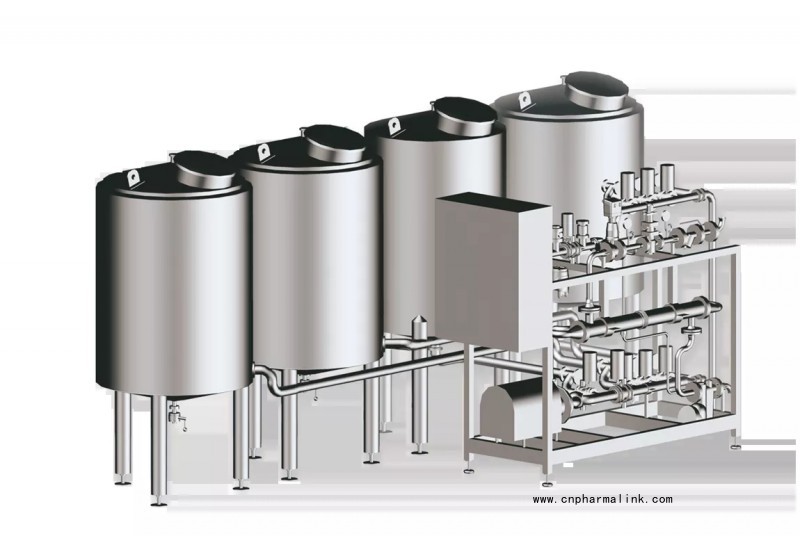

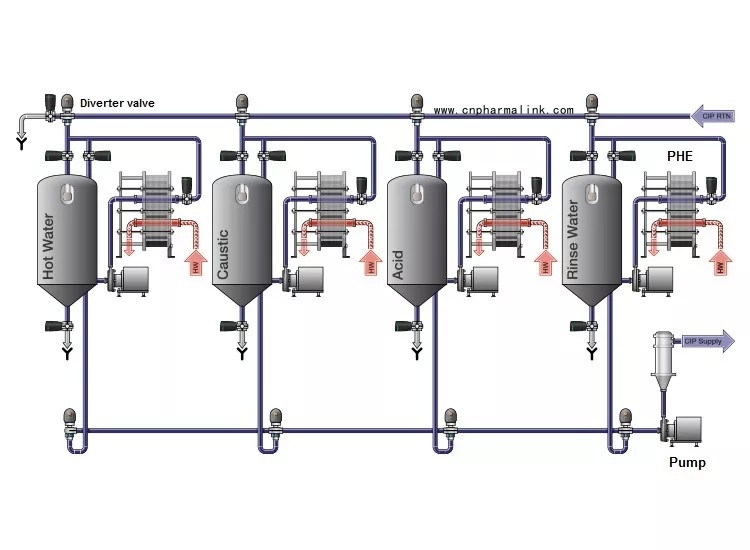

With the implementation of GMP 2010, it is essential to control drug quality risks. For the sake of quality assurance on purified water for injection, water for injection process pipeline and preparation system, the traditional manual cleaning and semi-automatic cleaning methods must be eliminated. This paper introduces the development trend of CIP system in detail, the working principle of CIP cleaning system, the design and application of system hardware and software, the comparison of CIP cleaning effect, and the technical requirements and acceptance standards of automatic control system. We design, develop, manufacture, supply and install Mobile and Fixed CIP & SIP Units for sanitization and sterilization. The units are custom made, modular, skidded in automated or semi-automated Models as per the 6 required time cycle for cleaning and sterilization as a part of cGMP requirements from portable to large fixed Multi-Tank system.

Note: the system is customized as per URS. All the pictures and videos are shot and produced by KEAN.

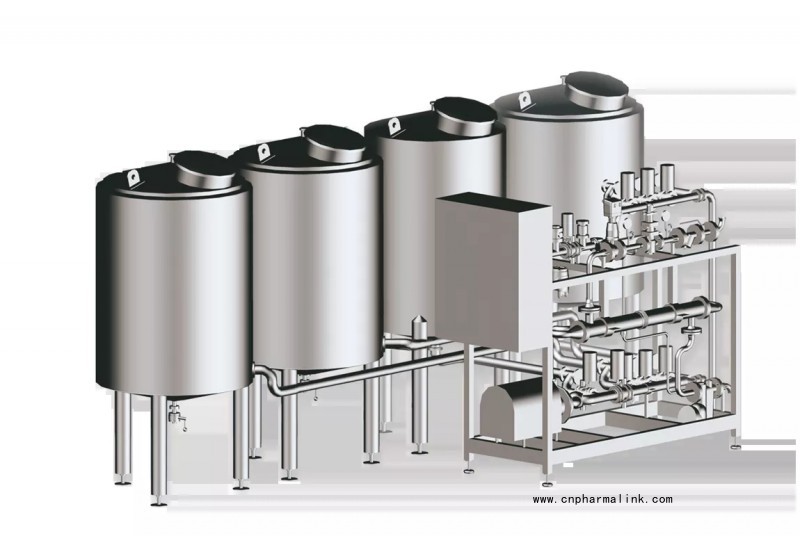

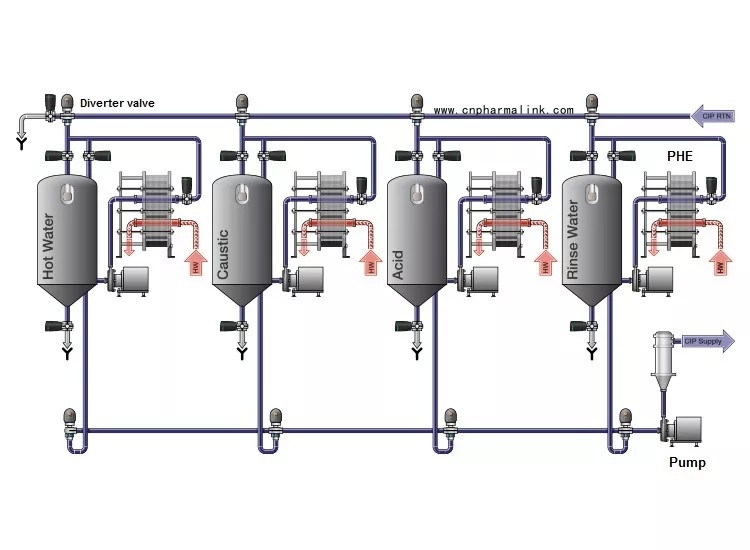

We offer automatic CIP system, ranging from single or multiple tank systems for pre-rinse, acid or caustic wash recovery, and reclaim or reuse.

Operational Sequence

- Flushing

- Alkaline or acid cleaning

- Final water rinse

CIP generally denotes heating the system employing saturated steam under a pressure of approximately at temperature 50-80 ℃.

ADVANTAGES

- Design and fitted to clean 100% of the machine.

- Cleans areas normally unaccessible on a manual sanitation.

- Reduce production downtime and faster than manual cleaning.

- Online validation with PH / Sensor & Final wash with Conductivity sensor.

- Cycle runs till PH and conductivity of supplied purified water and CIP solution starts equalizing.

- All these cycles are automatically maintained by PLC having display and records.

CIP Systems are engineered to your specific plant application, layout and utility requirements for effective and efficient sanitary process equipment cleaning.

CIP system is applied in sterile preparation mixing system, oral liquid mixing system, biological preparation mixing system, etc

Detailed Images

cleaning tank Filter

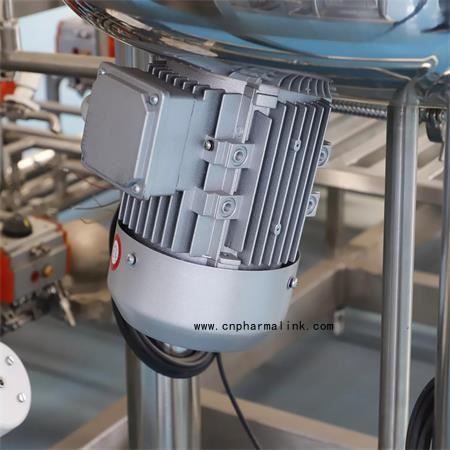

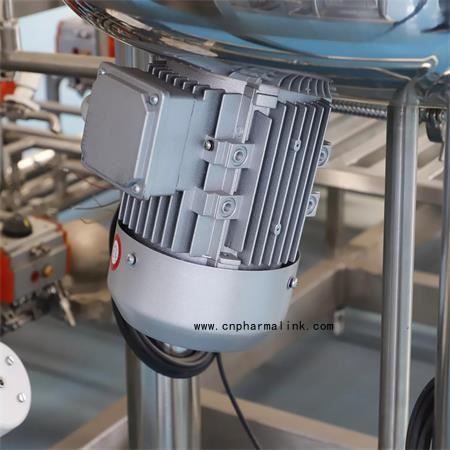

Motor PLC

Company Introduction

WORK SHOP

Certification

Trade show

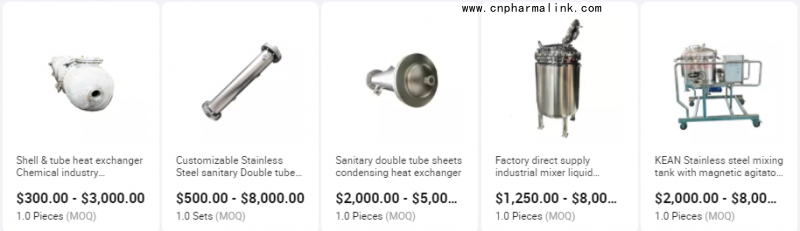

Supplier's popular products

Related Products/Recommended by seller

Overview/Quick Details

| Place of Origin: | Hebei, China | Max Working Pressure(MPa): | 10 MPa |

| Brand Name: | KEAN | Design Standard: | ISO CE ASME BPE |

| Condition: | New | Working Temperature(℃): | 10 - 165 ℃ |

| Video outgoing-inspection: | Provided | Warranty: | 1 Year |

| Machinery Test Report: | Provided | Key Selling Points: | Easy to Operate |

| Marketing Type: | New Product 2020 | Applicable Industries: | Food & Beverage Factory, Energy & Mining, Food & Beverage Shops, Pharmaceutical |

| Warranty of core components: | 1 Year | Showroom Location: | None |

| Core Components: | PLC, Pressure vessel | Name: | Pharmaceutical Stainless Steel Fully automatic CIP/ SIP System |

| Dimension(L*W*H): | customize | Filling medium: | Liquid |

| Capacity: | 50L-50000L | Material: | 304/316L Stainless Steel |

| Weight: | 0.5-50TON | Working pressure: | 0-10Mpa |

| Volume (m³): | customize | Certification of storage tank: | ASME CE ISO |

| Inner Material: | 304/316L stainless steel | After-sales Service Provided: | Free spare parts, Field installation, commissioning and training, Video technical support, Online support |

| Outer Material: | 304/316L stainless steel | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Design Pressure(MPa): | 0-10 | Local Service Location: | None |

| Supply Ability | |||

| Supply Ability | 1000 Piece/Pieces per Year | ||

| Packaging & Delivery | |||

| Packaging Details | woods packing | ||

| Port | qingdao.tianjin |

Product Description

With the implementation of GMP 2010, it is essential to control drug quality risks. For the sake of quality assurance on purified water for injection, water for injection process pipeline and preparation system, the traditional manual cleaning and semi-automatic cleaning methods must be eliminated. This paper introduces the development trend of CIP system in detail, the working principle of CIP cleaning system, the design and application of system hardware and software, the comparison of CIP cleaning effect, and the technical requirements and acceptance standards of automatic control system. We design, develop, manufacture, supply and install Mobile and Fixed CIP & SIP Units for sanitization and sterilization. The units are custom made, modular, skidded in automated or semi-automated Models as per the 6 required time cycle for cleaning and sterilization as a part of cGMP requirements from portable to large fixed Multi-Tank system.

Note: the system is customized as per URS. All the pictures and videos are shot and produced by KEAN.

We offer automatic CIP system, ranging from single or multiple tank systems for pre-rinse, acid or caustic wash recovery, and reclaim or reuse.

Operational Sequence

- Flushing

- Alkaline or acid cleaning

- Final water rinse

CIP generally denotes heating the system employing saturated steam under a pressure of approximately at temperature 50-80 ℃.

ADVANTAGES

- Design and fitted to clean 100% of the machine.

- Cleans areas normally unaccessible on a manual sanitation.

- Reduce production downtime and faster than manual cleaning.

- Online validation with PH / Sensor & Final wash with Conductivity sensor.

- Cycle runs till PH and conductivity of supplied purified water and CIP solution starts equalizing.

- All these cycles are automatically maintained by PLC having display and records.

CIP Systems are engineered to your specific plant application, layout and utility requirements for effective and efficient sanitary process equipment cleaning.

CIP system is applied in sterile preparation mixing system, oral liquid mixing system, biological preparation mixing system, etc

Features:

* To rationalize production schedule and to improve production capacity

* To guarantee both operator and product safety

* Reduced consumption of cleaning agent, steam, water and production cost due to the use of high-performance components and innovative cleaning procedures.

* Increased the service life of machine parts

* Can be configured to operate automatic, semiautomatic or hand controlled units.

* To provide new levels of efficient and effective CIP operations, data capture, and real-time operation records.

* To provide effective, reliable and repeatable cleaning,

* Sanitary design to meet all cGMP criteria.

* Customize design as per URS technical document.

* Equipped with a temperature sensor and sampling valve, and the pipeline is equipped with double tube plate heating device to ensure the temperature stability.

* Online validation with PH/sensor and final wash with conductivity sensor.

* Modular design: Compact structure, easily to operation and maintenance.

* All operations are controlled via a touch screen HMI and PLC controllers.

* To rationalize production schedule and to improve production capacity

* To guarantee both operator and product safety

* Reduced consumption of cleaning agent, steam, water and production cost due to the use of high-performance components and innovative cleaning procedures.

* Increased the service life of machine parts

* Can be configured to operate automatic, semiautomatic or hand controlled units.

* To provide new levels of efficient and effective CIP operations, data capture, and real-time operation records.

* To provide effective, reliable and repeatable cleaning,

* Sanitary design to meet all cGMP criteria.

* Customize design as per URS technical document.

* Equipped with a temperature sensor and sampling valve, and the pipeline is equipped with double tube plate heating device to ensure the temperature stability.

* Online validation with PH/sensor and final wash with conductivity sensor.

* Modular design: Compact structure, easily to operation and maintenance.

* All operations are controlled via a touch screen HMI and PLC controllers.

Detailed Images

cleaning tank Filter

Motor PLC

Company Introduction

WORK SHOP

Certification

Trade show

Supplier's popular products

Related Products/Recommended by seller