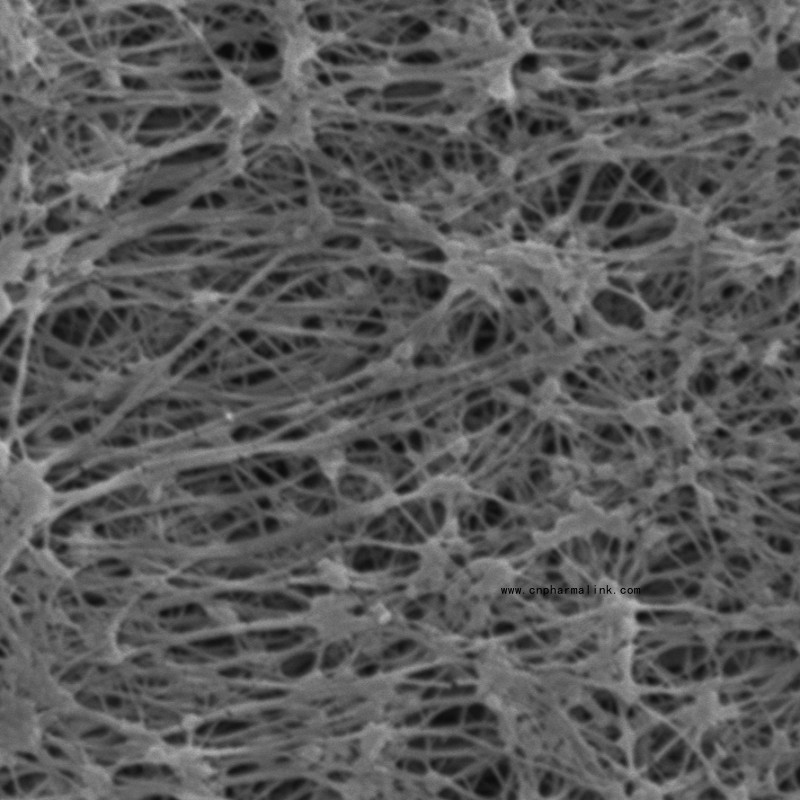

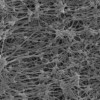

PTFE microporous membrane pleated filter element is made of natural hydrophobic polytetrafluoroethylene (PTFE) membrane and polypropylene material parts by advanced hot-melt sealing technology in a controlled Class-100 clean environment without any adhesive and surfactant, and meets the technical requirements of the national standard of the people's Republic of China GB / T 34244-2017 filter cartridge for liquid sterilization.

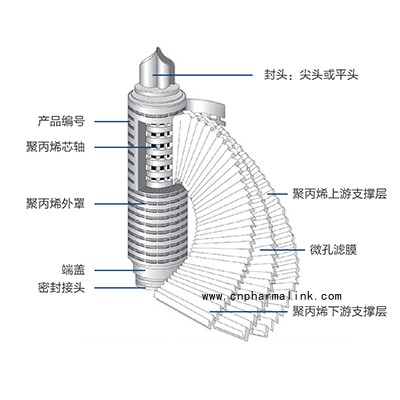

Material of filter element components:

Filter material : Natural hydrophobic PTFE membrane

Filter material : Natural hydrophobic PTFE membrane

Supports/Diversion : PP

Core/Cover/End cover/End caps : PP

Sealed leads/Fins : PP,Built in stainless steel

O-Ring : 222,226 silicon rubber etc.

Sealing technology : Hot melt without adhesives

Characteristics and features

Excellent high-tem resistance and extensive chemical compatibility.

All the compositions reach up to the requirement of the biological testing characteristics of USP Class 6 plastic products at 121℃ and the food contact materials listed in the relevant regulations of Chapter 21 of the Federal Regulations of the United States (CFR). They also conform to the requirements of China's "Standard for Hygienic Safety Evalution of Equipment and Protective Materials in Drinking Water" (2001) for drinking water transport and distribution equipment.

99.99995% bacteria retention in gas and liquid.99.99995% of all kinds of phages, bacteria and particles above 0.01μm were retained during gas filtration.

The sampling of filter element successfully passed the bacterial challenge test required by regulations, LRV≥7.Integrity can be maintained after repeated high-pressure disinfection.

Each filter element should pass the integrity test before leaving the factory. The limitations of integrity testing were correlated with the results of bacterial challenge experiments.

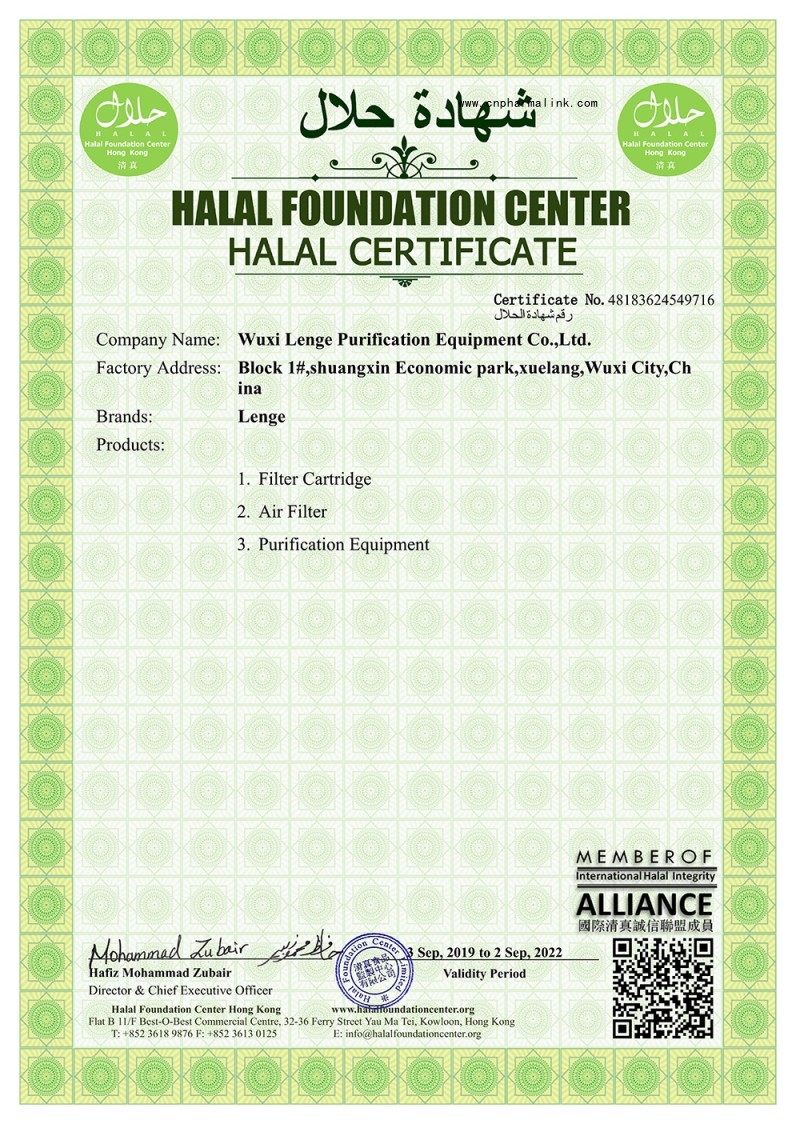

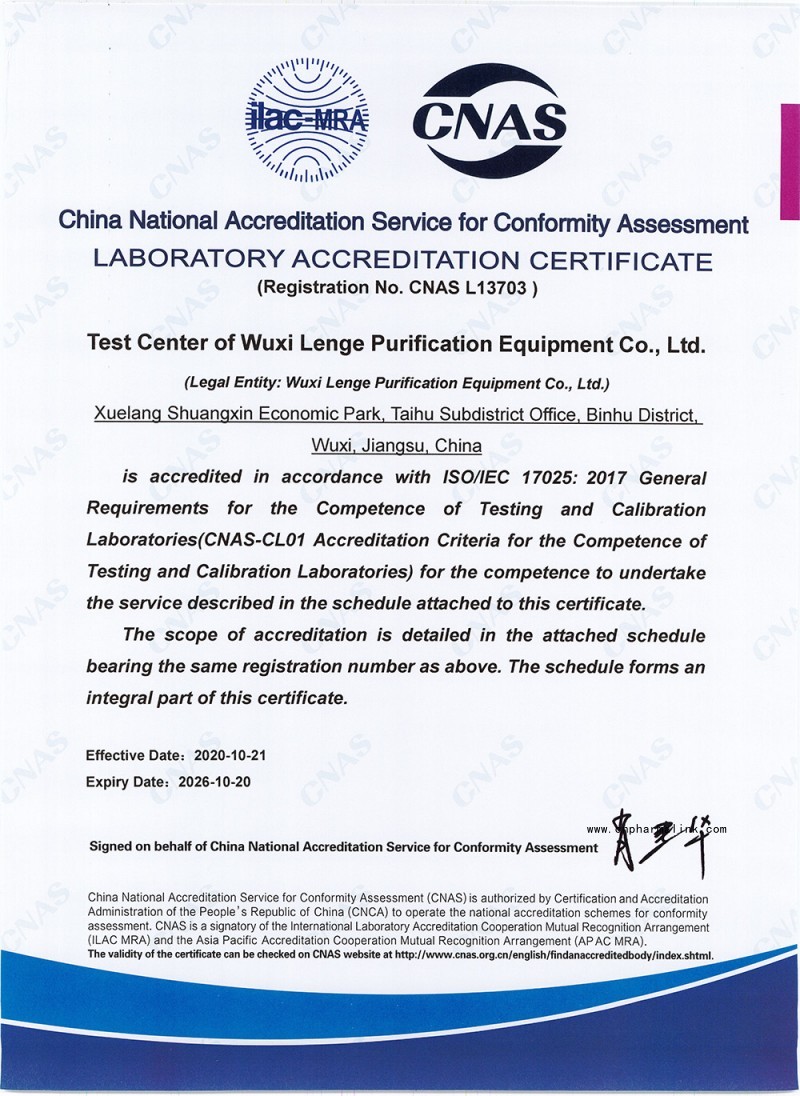

It is manufactured under ISO 9001 and ISO 14001 systems and Class 100 environment.

Production and usage are traceable.

Resistant to repeated steam sterilization.

large air flow, high efficiency and small volume.

Technical specifications and operating parameters

|

Size

|

Diameter: 2.75" (69 mm)

Length: 5"/10"/20"/30"/40" etc.

|

|

Filtration Area

|

Single 10" filter element is about 0.65m²

|

|

Minimum Bubble Point of Integrity Test Data

|

0.22μm: ≥ 0.13MPa (Import)

≥ 0.1MPa (Chinese)

0.45μm: ≥ 0.06MPa 23°C

60:40IPA: water(V:V)

|

|

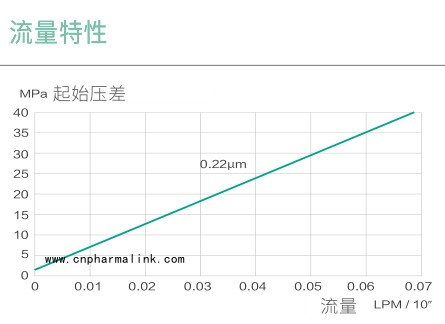

Typical Flow Aate

|

0.1um≥180Nm3 /h

0.22μm≥330Nm3 /h

0.45μm≥400Nm3 /h,

(P=0.2MPa, ΔP=0.01MPa, 20°C, 10" length)

|

|

Accumulated Steam Sterilization Time

|

121°C, 100 hours

140°C, 40 hours

Under experimental conditions

|

|

Maximum Differential Pressure

|

Positive:0.4MPa

Negative:0.2MPa

|

|

Recommended Service Life for Air Filtration

|

12 months for 60°C compressed air filtration

6 months for 80°C breathing port filtration

|

Typical application

Breathing port filtration of WFI storage tank.

Air inlet and exhaust filtration of large scale fermentation tank.

Breathing port filtration of medical intermediate storage tank.

Filtration of instrument gas in pharmaceutical industry.

Vacuum barrier of autoclave.

Transmission and filtration of air and other gases.

Gas filtration for aseptic packaging.

Sterilization and filtration of compressed air and CO2 in food and beverage industry.

Filtration of corrosive chemicals.

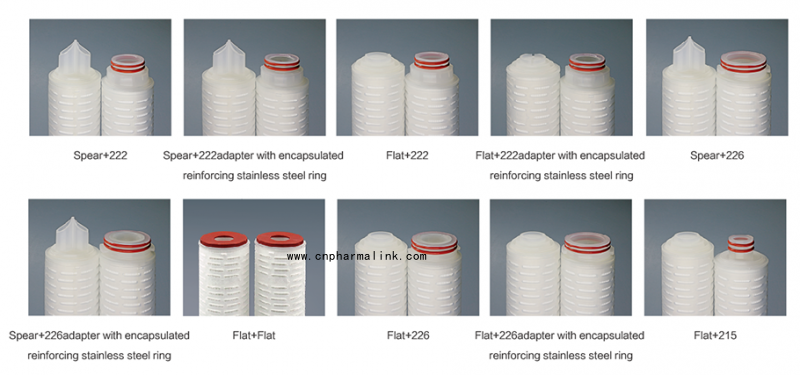

Adapter Style

Ordering information

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

|

|

PTFE

|

0.22

|

---

|

10

|

A

|

S

|

P

|

--X

|

|

1

|

Membrane

|

Hydrophobic / hydrophilic PTFE membrane

|

|

2

|

Pore size

|

0.1、0.22、0.45um

|

|

3

|

Length

|

5” / 10” / 20” / 30” / 40”

|

|

4

|

Connector/End Cover

A/AA/B/BB/C/CC/D/E/EE/F

|

Spear+222

Spear+222adapter with encapsulated reinforcing stainless steel ring

Flat+222

Flat+222adapter with encapsulated reinforcing stainless steel ring

Spear+226

Spear+226adapter with encapsulated reinforcing stainless steel ring

Flat+Flat

Flat+226

Flat+226adapter with encapsulated reinforcing stainless steel ring

Flat+215

Spear+3 Flange Bayonet adapter

|

|

5

|

Gasket Material

S、E、F、FF

|

S:silicon rubber

E:EPDM rubber

F:Fluorine rubber

FF:Encapsulated fluoroelastomer

|

|

6

|

Application P

|

Pharmaceutical grade for bio-pharmaceutical&food and beverage industry

|

|

7

|

Special Specification Remarks

|

Standard Specification Default

|

Note: The service life of the steam sterilization and other technical parameters are tested under strictly controlled experimental conditions. However, the actual operating conditions and experimental conditions will be different. For the application of a specific process, the performance of the filter needs to be verified and confirmed.