GZPTS700 Series Tablet Press Machine

Technical Data

|

Model |

GZPTS700-51 |

GZPTS700-63 |

GZPTS700-75 |

GZPTS700-81 |

|

|

Number Of Punch |

51 |

63 |

75 |

81 |

|

|

Punch Type |

D |

B |

BB |

BBS |

|

|

Turret Speed /R.P.M |

8~80 |

||||

|

Min Capacity(Tablets/H) Max Capacity (Tablet/H) |

48960 489600 |

60480 604800 |

72000 720000 |

77760 777600 |

|

|

Motor Power (KW) |

18.5 |

||||

|

Max Pre-Pressure (KN) |

100 |

||||

|

Max Main Pressure (KN) |

100 |

||||

|

Max Diameter(mm) |

25 |

16 |

13 |

11 |

|

|

Max Oblong Diameter(mm) |

25 |

18 |

16 |

13 |

|

|

Max Feeding (mm) |

18 |

||||

|

Max Thickness(mm) |

8 |

||||

|

Weight (kg) |

5800 |

||||

|

Size (mm) |

1430×1430×2250 |

||||

Advanced Introduction

GZPTS700 series double discharge high speed tablet press, using advanced modular design concept, simple structure.

The four-column frame structure ensures the stability of the machine. Novel and beautiful appearance, large space, clean, easy operation and maintenance.

GZPTS700 series double discharge high speed tablet press machine has the characteristics of high manufacturing accuracy, advanced automation level, fast production speed, stable and reliable operation, low working noise. Through the combination of innovative technology and intelligent control, make the machine more advanced, improve the production quality of drugs, improve the production environment, reduce labor intensity, reduce the loss of raw materials, reduce production costs .It complies with the functions of FDA Part11 electronic records and electronic signatures and audit tracking, which fully meets the audit and requirements of pharmaceutical regulatory departments. It is an ideal equipment for pharmaceutical factories to implement production technology transformation and new projects and meet the requirements of GMP.

Adopt modular structure design, convenient installation and disassembly, high interchangeability.

① The main and pre-pressure system adopts modular design, which is convenient for installation, disassembly and maintenance.

The main and preloading systems are designed for two groups of the same structure. The size of the main and prepressing wheels is the same, With interchangeable, the maximum main pressure is 100kN, the distance between the prepressing and the main pressure is relatively long, to ensure the full exhaust in the pressing process and the quality of the pressing tablets.

② The lower filling mechanism and the feeding device all adopt modular design, and the left and right sides can be interchanged

Filling and feeding mechanism are modular design, easy to disassemble and install.

All the components of the blanking mechanism are fastened by the handle, and the impeller is fixed by retaining ring

It can be disassembled without tools, and the operation is simple and convenient.

③ The machine adopts quick disassembly type upper and lower protective cover.

Tablet pressing room has a large visual space, upper and lower protective cover,

The feeding device, dust collecting device and other parts are clearly visible, upper and lower protection

The cover can be quickly disassembled and assembled through the handle, which can be used for cleaning the equipment, Convenient maintenance and overhaul.

3、Smooth and smooth feeding, uniform cloth, to ensure the stability of the sheet weight

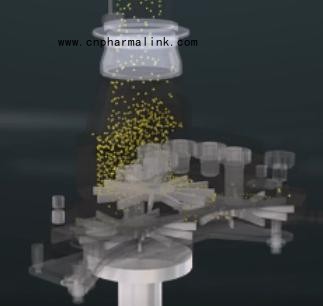

① The unique three-cavity filling structure is composed of double-layer three-paddle impeller

The forced feeding device is used for feeding.

The material passes through the feeder through the distributing impeller, filling impeller and metering impeller

Rotate evenly into the middle die hole. The impeller and the bottom of the material box remain relatively

Small clearance, to ensure that the material filling uniform, and to ensure that the material in the material box

It can still fill stably in the case of less, and improve the utilization rate of materials

② Feeding motor inverter control.

Siemens AC variable frequency governor is used to control the forced feeding motor

Achieving smooth start, overload protection, fault stop, speed adjustment and other functions.

It can adapt to the requirements of material performance and output, and adjust the blanking speed To ensure the filling of materials and the quality of tablets.

③ vertical feeding

The lower hopper, gear box and material box are in the same axis, and has a large aperture Connected port, ensure smooth material feeding, improve the flow of material, ,Provide guarantee for stable filling of material.