technical parameter

|

eye |

technical parameter |

Prepare for annotations |

|

Maximum production speed |

300 Boals / min |

|

|

Applicable to bottle body |

Hobin: 25-100 mm |

|

|

Small round bottleφ25~φ100mm |

|

|

|

Applicable bottle height |

45~200mm |

|

|

source |

AC220V 50/60HZ |

|

|

power factor |

2.0KW |

A vacuum cleaner |

|

manner |

0.5~0.7Mpa |

|

|

gas consumption |

About 80L/min of clean air |

|

|

size |

Approximately 2650mm (L) 1250mm (W) 1820mm (H) |

|

|

weight |

About 660kg |

|

operational principle

manually add the bottle to the bottle warehouse, and the bottle is automatically quantified and set by the bottle is transferred to the plate in the plate at the high speed, and the handling part of the bottle is the position and electronic position of the bottle at the specified direction and speed; What is the process of the electronic control system?Remember?Remember?Realize the fully automated operation requirements.

(Can also be marked for reference)

l Special point number of products

l Plastic bottles, such as round bottles, square bottles and alien bottles, have a larger transaction scale, and a larger transaction scale;

l Refrigerator, automatic report prompt function;

l Automatic replenishment of overmaterial level and stop function;

l The transmission line is equipped with the bottle blocking function, the rear bottle blocking bottle is automatically stopped, the bottling is automatically assisted, and the wood needs to set sail manually;

l Fast speed and low noise;

l All Chinese touch screen, PLC control, simple operation, good interface, adjustable adjustment parameters;

l The fault automatically determines, and returns the sound and light report to the police and the president of the monitor department;

Use AISI 304 no material, meet GMP requirements;

loppinga.

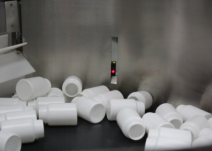

Material and lift machine posture

l "Warehouse capacity is not large, large capacity," "data", "data", "automatic report";

l Warehouse warehouse door can automatically open through touch screen control, appropriate feeding, prevention;

l AISI 304 is excluded and meets GMP requirements;

Engineering plastic, meet GMP requirements.

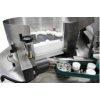

Look like b. The bottle handling machine

l The bottle is lifted into the bottle plate, which quickly rotates the bottle in the specified direction;

l Elbow wheel cleaning and reverse specification bottle;

l On the number, she will send to the number, and on the number, she will send to the number.

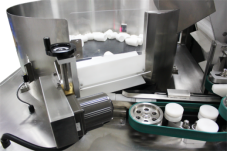

c. Bottle delivery posture

Past days, past days, past days, past days;

The same was my life in past days.

The d. Bottle posture

When taking the number, take the number, take the number, take the number, take the number, take the number, take the number, take the number.

e.Optional aircraft

Option to clear the inside of the plastic bottle.The function of turning the bottle down to remove the complex