Number of technical participation:

|

order number |

eye |

technical parameter |

|

1 |

module |

Infineon |

|

2 |

Material door cylinder |

Festo |

|

3 |

change |

Danfoss |

|

4 |

Shake cylinder |

Festo |

|

5 |

Door power |

Festo |

|

6 |

Intake regulator |

SMC |

|

7 |

Grey head soil face |

SMC |

|

8 |

Color touch screen |

The Windows10 control system dominates the industrial power |

|

9 |

Force begins |

SMC |

|

10 |

The trip begins |

Omron |

|

11 |

The rush to stop began |

Schneider |

|

12 |

photosensor |

Optex |

|

13 |

Middle electricity |

Omron |

|

14 |

Small isolation switch |

Schneider |

|

15 |

Report the police lamp |

PAL |

operational principle:

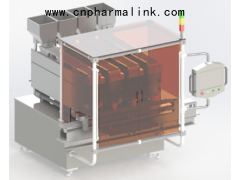

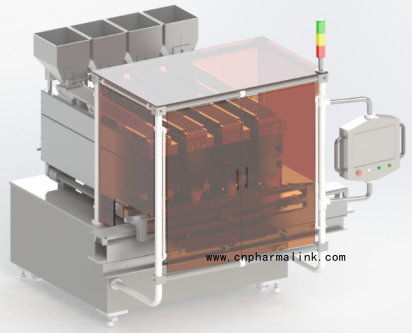

TV program digital grain machine name is organized by a TV program jointly organized, gift compared with computer number grain machine, equipped with full seal, visualization, simple ending, driving, convenient exchange and other characteristics.Kanamite module is abundant, 6,8,12 three, with developed ability, ability and ability of the principle of organizational ability is divided into the following four steps: 1, cool delivery speed; if the agent is used a difference in size, shape and surface luminosity, the two resistance is relatively high.

2. Fixed quantity of particle lines; in the case of specified quantity, according to the requirements of customers, use as many daily working hours.

3. Number of Southeast Asian mold organization: the module array granularity machine is composed of the basic domestic organization. The loading amount of how many bottles should be selected for each part is quite rich, such as the loading quantity is 100 grains / bottle

4. Number of mouths under grain machine; perseverance industry customers generally ask for production speed in URS, industrial speed and quantity of feeding mouth. According to the interval time of bottle, tank and release inspection, the fixed working rate of each feeding mouth is about 50 bottles / points, 100 bottles / points, 2; 200 bottles / points, 200 bottles / points.

This item recommended the use of analog grain machine, using the following 24 3 kinds of mouth posture, there is a number of grain precision, fast, use all night flat night accounting, inclusive, completely solved is the equipment easy to bad, eliminate poor effect, exchange cumbersome shortcomings, since this problem, has got a lot of users.

Considering the order type 8-10 coating sheet, the capacity of 28 grains / bottle, energy of 2000-3000 bottles / day, it is recommended to use 8 South African model combination multi-grain machine, energy requirements.

(The picture may not be fit for reference only)

Product characteristics

l Matrix photoelectric plate: the core of the photoelectric number machine is photoelectric number head, a number of particle machine count is due to the accuracy of the number head is not standard, we from the first generation of photoelectric head research and development, into repeated iteration, currently using 4 groups of emission, 8 groups to accept the matrix photoelectric plate without blind area, to ensure the basic requirements of several grain precision.

l Single chip main board and software computing system: we use the latest released Infineon high-speed chip (infineonSAF-XC164CS-32F40F), single chip using supporting independently developed V3.0 software system, compared with the traditional digital particle machine faster, data processing ability, analysis data of different particle drop forms is more complete, stronger error tolerance and error correction, so as to ensure the accuracy of digital head reached 100%.

l Vacuum coating optical glass: the traditional photoelectric head lens cover plate for ordinary glass, we improve for the vacuum coating optical lens glass, reduce the stray interference of infrared propagation process, but also reduce the dust on the lens surface attachment situation, the design can ensure the precision of several grains and extend the continuous working time of the photoelectric head in the state of dust.

DC control distributed disc: using DC servo Wuji control system, multi-level disc intelligent chip control, each level frequency can be adjusted separately, with vibration disc real-time feedback (MT-ABS feedback self-adjustment system), to make the vibration delivery materials more stable and efficient.

l Drive parts and drug isolation: the traditional number grain machine cylinder expansion rod directly contact drug particles, is very easy to damage, module number grain machine using drive, vibration, control three parts of separate partition seal, and drug isolation structure, the drive parts will not contact materials, greatly extend the service life of the cylinder, reduce the cost of later use and maintenance.

l Visual panel: The particle drop process of the traditional electronic array granularity is completely closed and invisible, while the module array granularity adopts a visual structure. When the particle drop process is abnormal, the operator can find the investigation problem in time.

l Rotary gate: the traditional electronic machine uses linear gate, long cylinder stroke causes long cutting time, easy to cut off or medicine, affect the precision of the machine.Our module number grain machine uses the rotating material gate instead of the traditional linear material gate, the cutting speed is doubled, even if the number grain accuracy of small particles below 3mm can be guaranteed.

l Closed negative pressure dust removal system: the microhole negative pressure vacuum suction device is designed to effectively remove the dust carried in the medicine particle. Compared with the extended continuous working time of the traditional digital particle machine, even the vegetarian wafer with large dust can also achieve continuous production without downtime.

l Tool-free quick disassembly structure: the structure of the photoelectric box and cylinder box of the traditional digital granularity machine is more complicated, and the replacement variety and cleaning are inconvenient. The module digital granularity machine adopts the modular structure design, and the disassembly of the digital granularity machine can be completed within ten minutes, which is very simple and easy to use.

l 17 # Windows10 industrial computer large touch screen: Due to the requirements for electronic traceability and electronic record in digital hardware upgrade and industrial intelligence, our module digital computer uniformly adopts 17 # industrial computer and Windows10 operating system, which has good data transmission and data sharing ability for MES, SCADA, OEE and other software systems.