1. Machine Performance Overview

JY-300C Hard Capsule Filling Machine is our company independently developed, designed and produced, which can be completed (solution, suspension, microemulsion) filling equipment in a hard capsule. The ceramic pump is used to add liquid, and the servo motor controls the loading system to ensure the loading difference, accurate measurement, optical fiber detection, no liquid in case of lack of glue and automatic waste kicking function.

The machine adopts stepless variable frequency governor, which is convenient and intuitive to operate. As a new and convenient drug delivery mode and filling concept in the new century, the machine is the latest filling equipment for developing high-end products in pharmaceutical, food, health products and other industries.

1.1 The equipment adopts HMI control system to automatically alarm for lack of capsule and material.

1.2 The capsule feeding machine has a vacuum positioning and separation mechanism to make the capsule loading rate reach more than 99%. Optical fiber automatic detection, identification of missing capsules in upper and lower mold holes.

1.3 High precision ceramic pump and servo motor dosing system are adopted to control the loading difference at about ± 2% and the dose is accurate.

2. Working Principle & Sequence of Operation

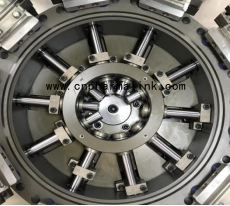

New closed turntable

The ten station rotary disc is integrally processed and formed to achieve compact structure, no splicing gap, good sealing, easy disassembly and maintenance. The upper and lower modules move separately (the lower mold makes horizontal expansion movement, and the upper mold makes vertical lifting movement). The fixed support shaft of the upper and lower modules is sealed with oil retaining and dust-proof double lip bone dust ring. It has the advantages of no noise, small volume, small load and high-precision fully enclosed rotary disc. The interior is free of maintenance and repair within three years. [Patent No.: 2015 2 1021530.0].

|

Station 1 |

Capsule Separation

|

|

Station 2 |

Upper and Lower capsule Mold Separation

|

|

Station 3 |

Photoelectric Test Whether The Capsule is Separated Normally

|

|

Station 4 |

Filling liquid

|

|

Station 5 |

Add Smaller Capsules (Mixed Filling)

|

|

Station 6 |

Rejection of Unopened and Damaged Capsule

|

|

Station 7 |

Idle

|

|

Station 8 |

Capsule Closing

|

|

Station 9 |

Finished Capsule Outlet (Connected to Capsule Sealing Machine)

|

|

Station 10 |

Upper and Lower Mold Reset

|

|

High-precision Ceramic Pump

|

The liquid filling mechanism adopts high-precision ceramic pump and servo motor liquid filling system to control the difference of liquid material loading in the capsule at about ± 2% and measure accurately.

|

|

|

The new capsule sowing frame adopts guide rail transmission mechanism, with high operation accuracy and long service life. The closed design prevents the entry of waste capsules and dust, so as to ensure the rapid and orderly sowing of capsules and the accurate direction adjustment of capsules.

|

High Precision Optical Fiber Detection System

Due to its fast reaction speed, optical fiber sensing can realize non-contact detection, with high precision, high resolution and good reliability. The equipment can quickly detect whether the hollow capsules are normally separated in the production process. If there are abnormal and unseparated hollow capsules, the optical fiber system transmits the collected data to the liquid filling station and waste kicking station after detection, and the equipment operates to the liquid filling station, According to the data analysis of the optical fiber detection system, the liquid adding station stops adding liquid, the equipment runs to the waste kicking station, and the abnormal non separated hollow capsules are removed, which ensures the stability of the equipment in the production process.

3. Technical Parameter

|

Production Efficiency

|

300Capsules/minute

|

|

Filling Material

|

Oil, Solution, Suspension or Paste

|

|

Number of Die Holes

|

6 Holes

|

|

Refillable Capsule Size

|

00-4# |

|

Power

|

380V 50Hz 5KW |

|

Weight

|

750KG |

|

Dimension

|

860*960*1800mm |

|

Liquid Loading Accuracy

|

±2% |

4. List of Main Electrical Accessories

|

Name

|

Spec./Model

|

Qty

|

Brand

|

|

Touch Screen

|

6AV6648-0BC11-3AX0 |

1 |

SIEMENS

|

|

PUC Programmable

|

6ES7/288-1ST30-0AA0 |

1 |

SIEMENS

|

|

Inverter

|

ATV320U15N4C |

1 |

Schneider

|

|

Intermediate Relay

|

MY2NJ |

2 |

OMRON

|

|

AC Contactor

|

3TB42 |

4 |

SIEMENS

|

|

Switch Power

|

S-50-24 |

1 |

Mingwei

|

|

Main Motor

|

R37DM90LS4 |

1 |

SEW |

|

Servo Motor

|

LXM16DU04M2X |

2 |

YASKAWA

|

|

Vacuum Pump (Dry)

|

KRX3-P-VB-03 |

1 |

ORION

|

|

Detection Optical Fiber

|

— |

12 |

Panasonic

|

|

Ceramic Pump

|

0.2-0.5ML |

6 |

Xinxiang

|

|

Drive Bearing

|

Bearing series |

90 |

Osaka

|

|

Indexing Box

|

RU-100DS10 |

1 |

Daojin

|

|

Deduster

|

XLJA series of |

1 |

Self Produce

|

Approximate price:USD11000~15000

Minimum order quantity:1set

Delivery time:45~60days after deposit

Terms of transaction:FOB, CIF

Payment terms:30% Advanced