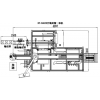

Automatic Master Carton & Case Packing Machine KY-500ZX

Automatic Master Carton & Case Packing Machine KY-500ZX

I.Main Use :

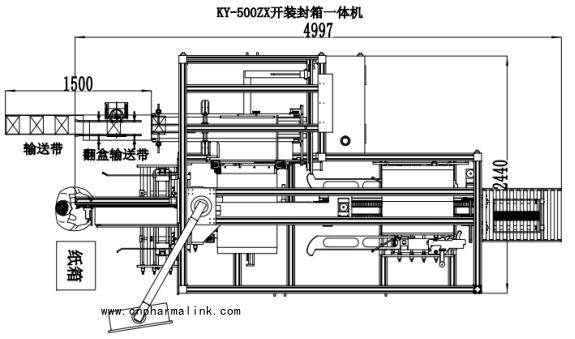

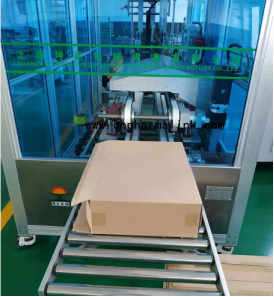

KY-500ZX Master carton packing machine are packaging systems which erect, close and fill sealed cartons. they pick up a flat carton (known as a blank), erect it into a rectangular shape, push the product into the carton (or fill it through a vertical flow), and close the carton via end flaps or a fold-over lid. Machines can be semi-automatic or fully automatic.

KY-500ZX Master carton packing machine is designed for installation downstream of the packaging line, but also as an independent unit.

It occupies small area ,save a lot of installation space.

II.Applications:

KY-500ZX Master carton packing machine are used in all fast moving consumer goods sectors but especially pharmaceuticals,food, confectionery, tobacco, tea and coffee, , toiletries, cosmetics, household products and etc.

III.Performance characteristics:

1. Compact, reduced size, high speed up to 18case /minute with multiple pick & place.

2. Automated adjustments.

3. cartoner machine equipped with whole set Siemens configuration. Servo motor.

4. All Siemens PLC 5 points reserved for docking MES and ERP system data.

5. series number for each spare part , it make us scientific management conveniently, and ensure the customer maintain equipment and replace spare parts more precise and fast.

6. Surface treatment of every spare part is strictly controlled precision in processing and assembling. Such as every spare part is wrapped with newspaper one by one avoiding scratches on the surface, etc

7. focus on high quality equipment, carefully polished every spare parts to the best before assembly, most of spare parts are polished by grinding machine, guarantee the stability of equipment operation and reduce the noise in running.

IV.Technical Parameter:

|

No. |

Name |

Value |

|

1 |

Output |

6-18 case/min. based on product. |

|

3 |

Power |

3KW |

|

4 |

Vacuum suction (self-vacuum pump) |

0.6MPa |

|

5 |

Weight |

1800KG |

|

6 |

Shape size (connection part is not included) |

L3500 * W1800 * H2000 mm (customized according to carton size) |

|

7 |

Working voltage |

380V/50HZ |

V.Configuration:

|

No |

Name |

Model |

Brand |

QTY |

|

1 |

Touch screen |

GS2107-WTBD |

Mitsubishi |

1 |

|

2 |

PLC |

FX3SA-30MT-CM |

Mitsubishi |

1 |

|

3 |

Frequency converter |

FR-E740-0.75K-CHT |

Mitsubishi |

1 |

|

4 |

Miniature circuit breaker |

OSMC32N3C16 |

Schneider |

1 |

|

5 |

Miniature circuit breaker |

OSMC32N1C6 |

Schneider |

3 |

|

6 |

With leakage circuit breaker |

EA9RN4C3230C |

Schneider |

1 |

|

7 |

Relay |

MY2N-J/DC 24v |

Omron |

6 |

|

8 |

Relay base |

PYF08A-E |

Omron |

6 |

|

9 |

Encoder |

OVW2-036-2MHC |

NEMICON |

1 |

|

10 |

Switching power supply |

NES-100-24 |

Mean Well |

1 |

|

11 |

Conveyor motor |

90YT90GV22 |

Xiamen |

2 |

|

12 |

Gearbox |

90GF6H |

Xiamen |

0 |

|

13 |

Speed controller |

SF90E |

|

2 |

|

14 |

Clutch |

DLK1-5AT |

Xiamen |

1 |

|

15 |

3-phase asynchronous motor |

CH750-15SZ |

Taiwan |

1 |

|

16 |

Oil free vacuum pump |

AP-2000C |

Auto Bo |

1 |

|

17 |

Check box photoelectric |

PM2-LF10 |

Panasonic |

1 |

|

18 |

Check box photoelectric wire |

CN-13-C3 |

Panasonic |

1 |

|

19 |

Proximity switch |

PSC1205-NP |

LeCroy |

1 |

|

20 |

Check photoelectric |

GTB6-N1211 |

ShiKe |

1 |

|

21 |

Solenoid valve |

4V210-08/PT terminal |

AirTAC |

3 |

|

22 |

Vacuum valve |

VT317V-5G-02 |

SMC |

1 |

|

23 |

Optical fiber |

FX-311 |

Panasonic |

1 |

VI.Terms and Condition:

1. Lead time: 30 working days after advance payment received .

2. Port of Loading: Shanghai , China.

3. Payment: 50% advance payment by T/T, and 50% balance payment before shipping.

4. Packing: standard export wooden case.

5. Warranty period: one year since the date of ETA

6.Service :We provide the installation&operation training by videos ,written instructions and remote assistance during the period of Covid-19;Door to door service will be provided after the whole situation get normal .

VI.Why Chose us :

1.-Increase production capacity

Cool Young automatic packaging line will increase production capacity to 400~800% for you .

2.-Save labor cost.

Cool Young automatic packaging line will save labor cost by 70~90%

3.-Reduce wastage

Cool Young automatic packaging line will save package material by 10~30%

4.-Establish Standardization production system.

As known to all ,hand made products are not stable on quality,speed,wastage &shapes ,cool young automatic packaging line can make all these factors are consistent .