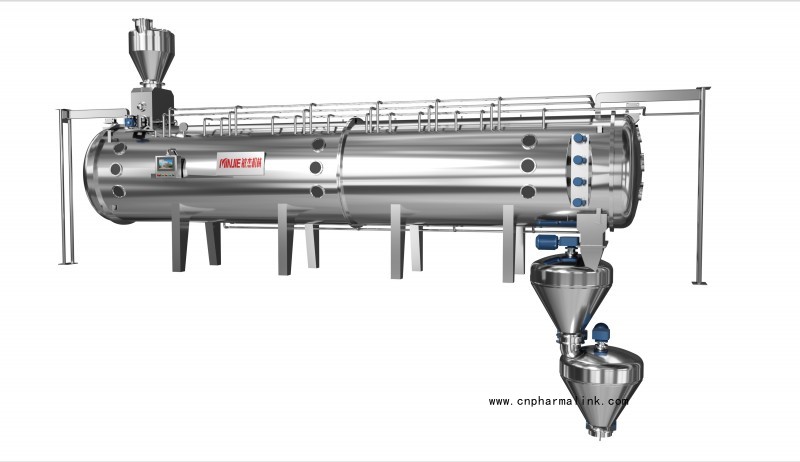

There are 3-11 layers of conveyor belts inside the cylindrical shell, the more the layers, and the larger the capacity. By feed and distributing device, the wet solid material is input continuously, and then distributed evenly on the conveyor belt under vacuum. Motion of the belt stirs the materials constantly, which speeds up evaporation, thus shortens the drying time, and also makes sure homogeneity during drying. The drying temperature and drying time (from feed-in to discharge) are adjustable(20-150℃)(20-80min). If the dried product needs granulation, it can be comminuted under vacuum, no dust flying appears, which increases products’yielding and avoid contamination. The dried product is discharged continuously by vacuum discharging and collecting device. Organic solvent in the wet materials can be recycled by our system, removing pollution problem caused by traditional dryers, and adding profit.

TECHNOLOGICAL PROCESS

EQUIPMENT ADVANTAGE

●Continuous feed-in, dry, granulate, discharge in vacuum state

●Less labor cost and energy consumption

●Excellent quality of the products

●Completely closed system, simplified processes and no contamination

●Little loss of product and solvent recycling possible

●Adjustable drying temperature (20-150℃) & drying time (20-80min)

●PLC automatic control system & CIP cleaning system

●GMP Standards

APPLICATION SCOPE

Industries: pharmaceutical, food, chemical, biological;Drying material state: solid, crystal, particle, powder, pills, fruit & vegetable slices or chips, leaves, etc;Some special material: easy oxidation, easy explosion, strong stimulation, high toxicity;Material needing solvent recycling.

EQUIPMENT SPECIFICATION

|

Model |

Diameter |

Length |

Height |

Heating area |

Heating temperature |

Moisture contentoffeeding material |

Moisture contentof dried product |

Heating resource |

Water Evaporation |

Dryer Body Power |

|

|

mm |

mm |

mm |

㎡ |

℃ |

% |

% |

|

kg/h |

kw |

|

MJG15-3 |

1400 |

7500 |

3000 |

15 |

20-150

|

10-80

|

0.3-5

|

Steam or Hot water or Hot oil |

8-12 |

6.00 |

|

MJG35-5 |

1600 |

9800 |

3300 |

35 |

18-25 |

8.00 |

||||

|

MJG50-5 |

2200 |

11500 |

3800 |

50 |

25-35 |

12.00 |

||||

|

MJG70-5 |

2200 |

13500 |

3800 |

70 |

35-45 |

12.00 |

||||

|

MJG80-5 |

2200 |

15500 |

3800 |

80 |

40-60 |

12.00 |

||||

|

MJG120-7 |

2300 |

16000 |

4200 |

120 |

70-90 |

15.00 |

||||

|

MJG160-9 |

2500 |

16000 |

4500 |

160 |

90-120 |

17.00 |

||||

|

MJG220-11 |

2800 |

16000 |

4500 |

200 |

120-150 |

19.00 |

EQUIPMENT SPECIFICATION

If the solvent of raw material is organic (ethanol, acetone, methanol etc.),evaporationcapacity would rise. Evaporation capacity is closely related with drying temperature.