The difference between products and similar low-end products

1. Pure new material: plastic injection parts in the production process will produce rods (molten plastic in the mold before entering the cavity flowing through the track after cooling). In order to save costs, general processing enterprises will recycle the rod after crushing it for two times, and use the mixture of new material + material or even the whole material or other waste materials to produce. The product produced with this kind of raw material has been melted once, so the strength, corrosion resistance, high temperature resistance, anti-aging and other indicators can not reach the standard of pure new material, the most important is easy to adulterate heavy metals and other harmful substances in the recycled material, can not reach the environmental protection and health standards. The company's products using pure new material production, without adding any material bar and other second-hand materials, the production process of material bar all do waste treatment. Ensure product performance and environmental protection to the highest standard (actual detection is not low content but not detected).

2. Sealing difference: sealing is an important indicator of pagoda joint, some customers have such experience: using low-end

No matter how tight the pipe and tie belt are used in the joint, it cannot prevent the slow air leakage after the system is pressurized. The reason is that low-end joint manufacturers adopt simple split mold production in order to save production and mold cost. Mold opening and closing can produce 8,10 or even 20 joints at a time. The result is that the resulting joint as a whole has a split wire left behind (the technical term is the die line). Because of the existence of this line, so no matter how to deal with the gas or liquid in the process of use will slowly leak along the line, can not be made up.

Products of our company did not avoid this problem, do not hesitate to improve the mould cost and production cost, increase the pump structure, pagodas first part of the whole generation first, and then die off, perfect to avoid the pagoda head part of the moulding line, solves this problem once and for all, at the same time this kind of products of the mould structure pagoda head part is smooth and round, not oval, And silicone tube fit evenly, again reduce the possibility of leakage.

Pure new material and non pure new material distinction: non pure new material products as a whole dark yellow or light gray, dull surface, transparency is not high. The color of a single product is not obvious, the more the quantity or the higher the proportion of rods added, the more obvious.

|

Specification/color classification |

|

|

A:3.9mm(5/32)-6.4mm(1/4) |

F:1.6mm(1/16)-3.9mm(5/32) |

|

B:3.2mm(1/8)-6.4mm(1/4) |

G:2.4mm(3/32)-3.2mm(1/8) |

|

C:3.2mm(1/8)-4.8mm(3/16) |

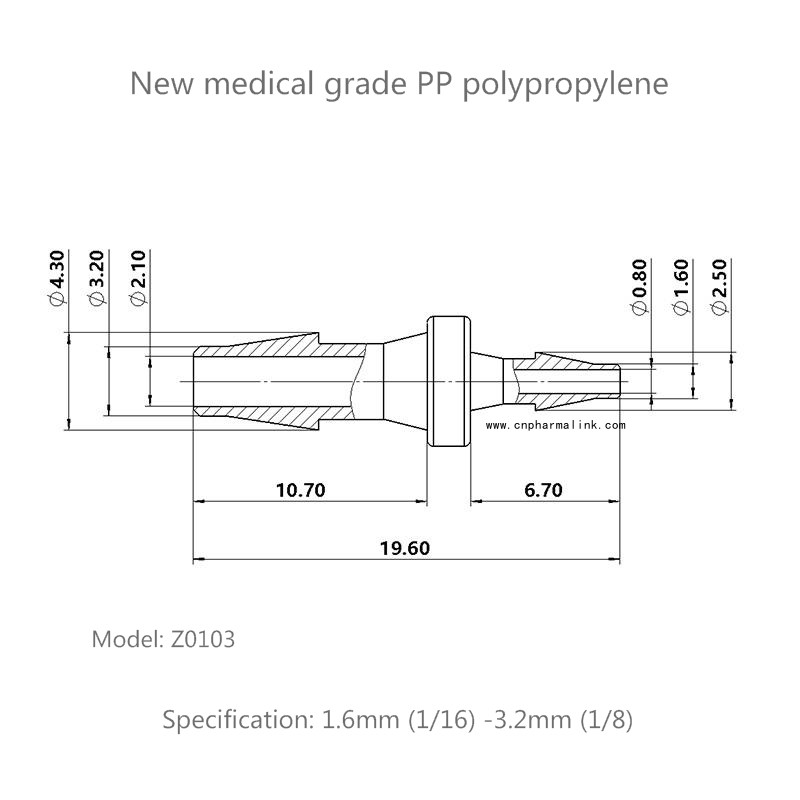

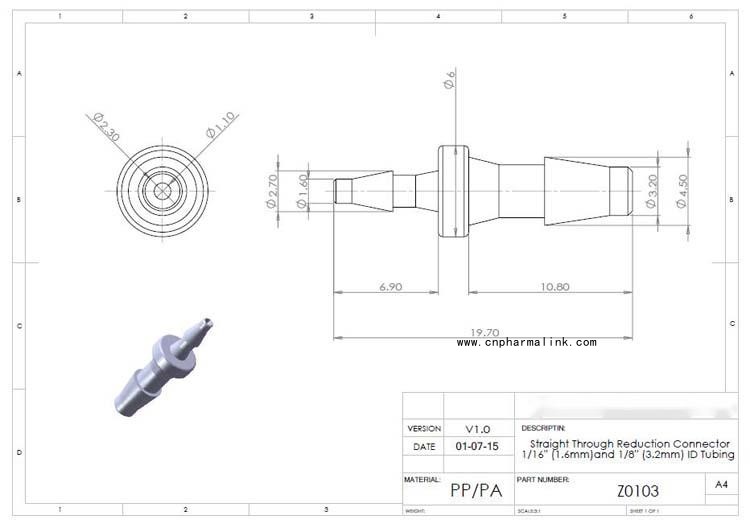

H:1.6mm(1/16)-3.2mm(1/8) |

|

D:2.4mm(3/32)-4.8mm(3/16) |

K:1.6mm(1/16)-2.4mm(3/32) |

|

E:2.4mm(3/32)-3.9mm(5/32) |

|