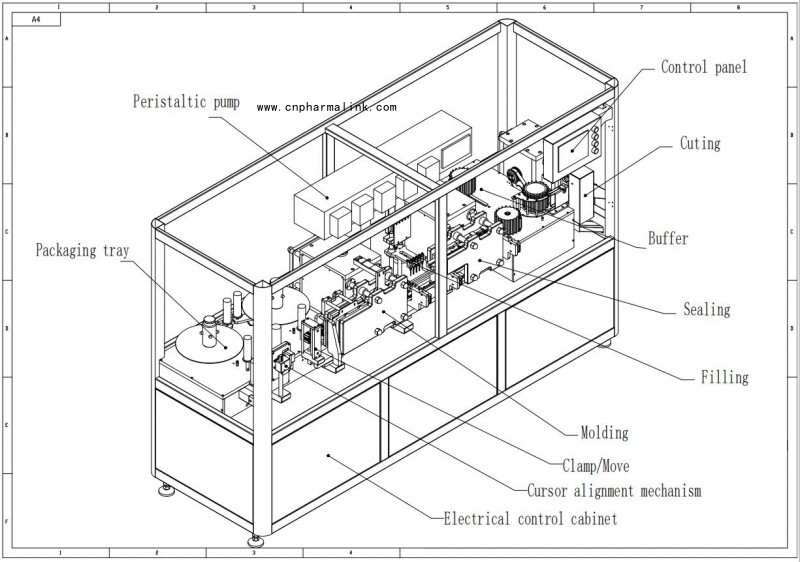

General introduction

Machine USES composite film or a single packaging material; Equipment adopts servo transmission,It has the function of color calibration;Forming and sealing die is realized by servo system;Fill with 5 heads;Servo power is used for shearing,Number of shear grains is set arbitrarily from 1 to 10.

Production process flow

Shell making molding→Servo transmission(Color calibration)→Filling(5 head)→ Sealing→Shear(1-10 gr)

Product feature

1. Machine is powered by Panasonic servo system.

2. This machine adopts Schneider low voltage electric appliance, Siemens PLC as the controller, Servo motion control is more accurate.

3. Servo motor is used to control the stroke, Color calibration is more accurate.

4. Servo motor is used to drive the forming/sealing die, Strength, Gentle movement, No impact force.

5. Servo motor is used as shearing power, Strength,Gentle movement, Shear grain number can be set arbitrarily.

6. Japan SMC series solenoid valve, Quick action response, Life is long.

7. Electronic peristaltic pump filling, Suitable for filling of different viscosity products, load accurately,Easy to adjust Settings.

8. 316L stainless steel is used for contact with medicine, Outer cover of the machine is 304 stainless steel, Whole machine conforms to GMP standard.

Technical specifications

1. Maximum forming depth:34mm

2. Filling quotas:5head

3. Production speed:110 bottle/min

4. Packaging materials:PVC/PE PET/PE Etc.

5. Filling capacity:1-100ml

6. Total power:8.5KW

7. Voltage:380V3P(220V/3P)

8. Overall dimensions:2634mm * 850mm *2000mm