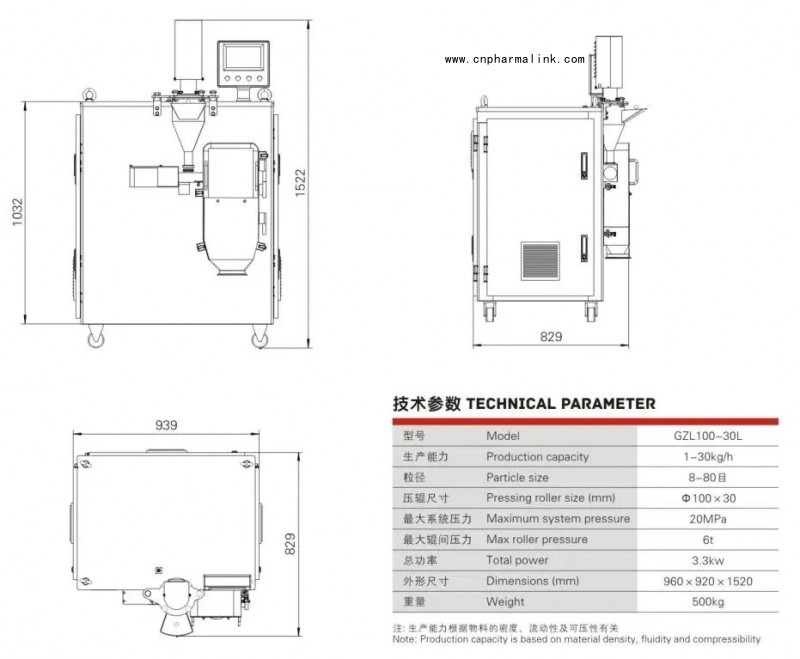

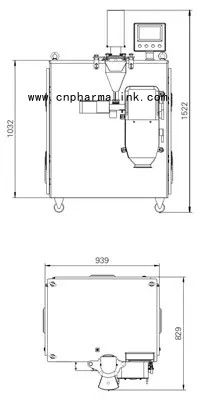

GZL100 Dry Granulator

Short Description:

The machine adopts two-stage screw feeding system andunique cantilever design,which improves the range ofprocessing materials and the success rate and vield ofgranulation;

Application

This model is mainly used for the development and research ofnew dosage forms of pharmaceutical research institutes and theproduction of small-dose traditional Chinese medicinepreparations.The minimum feeding amount is 20g.Speciallydeveloped micro-sample devices for precious raw materials,which are essential for precious and sensitive drugs.Lessgranulating equipment,widely used in pharmaceutical,food.chemical and other industries.

Feature

Applicable to LCD touch screen and a variety of automaticcontrol technologies to improve the flexibility and security ofthe equipment;The whole machine is of high-quality stainless steelstructure,and the moving zone is separated from the workingarea,which realizes clean and sealed production from powderto granule,and all material contact parts are easy todisassemble and clean;Ful compliance with GMP requirements for annual productionof drugs.In addition,the machine is equipped with a smallamount of material testing equipment,only need 20 grams ofmaterial to understand the nature of the material and reducethe research and development costs:The water-cooled pressure roller has a built-in structure forthe inlet and outlet,and the test material does not heat upduring the extrusion process,which affects the materialproperties.

Equipment Usage

The machine is used to make the dried powder into a certain density and particle size test equipment, which provides good fluidity particles for tablet making and capsule filling equipment. It is mainly used in the research and development of new dosage forms and the production of small preparations and APIs. To provide granules with good fluidity for tablet making and capsule filling equipment. The product meets the GMP requirements of drug production.

Dry granulation has the advantages of simple process, low energy consumption and convenient connection with the existing process. Compared with wet granulation, it has the advantages of no need of binder and solvent, and no problems of high temperature and solvent recovery. The granulation process can be completed with one feeding, which saves a lot of personnel and floor space.