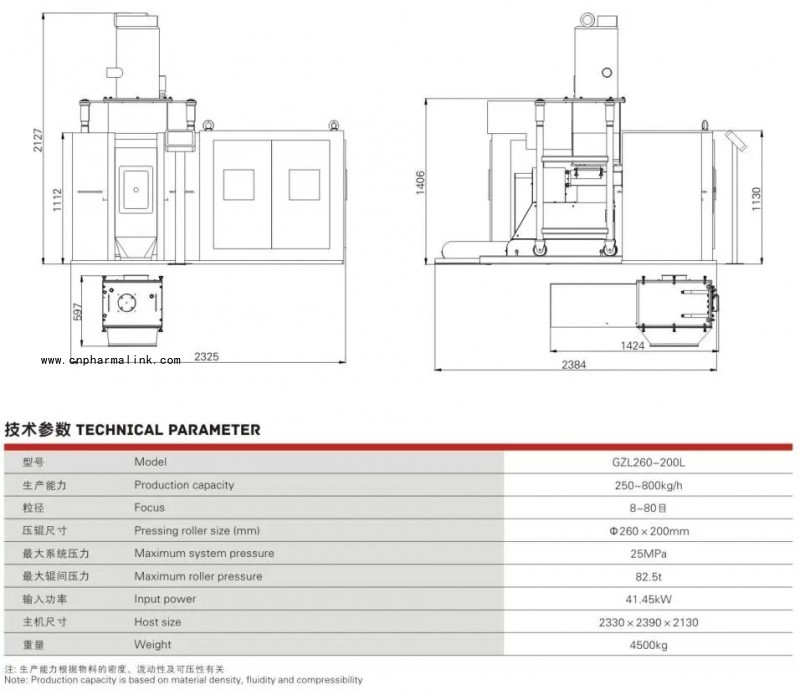

Gzl260 Dry Granulator

Short Description:

The contact part(work chamber)with the material is sealedindependently,and the seal is independent.

Application

Dry granulation is widely used in pharmaceutical,food,chemicaland other industries.It is especially suitable for granulation ofdrugs that are easily decomposed by moisture,easy to absorbmoisture,sensitive to heat,and the particles can be used fordensification to improve fluidity,tablet compression,Fillingcapsules and granules for bagging.This machine is especiallysuitable for mass production.

Feature

The contact part(work chamber)with the material is sealedindependently,and the seal is independent.

The seal is sealedwith two or more stages and the gas seal is used to ensurethe cleanliness requirement and the seal is more reliable.The two pressure rollers of the tableting system adoptuniversal joint shaft transmission,offset feeding structure,more reasonable design,more stable film formation andleading domestic.

The horizontal,vertical and monolithic parts are individuallymodularized and can be moved separately for easydisassembly and cleaning.

PLC system online control,LCD screen man-machineinterface operation,automatic feeding amount setting:vertical.horizontal,tablet,and whole grain are all set by frequencyconversion;system pressure,and online control and parametersfrom feeding to screening system Display and query.

Structure

The whole machine is composed of the following parts: integral frame, vacuum feeding system, vertical feeding system, horizontal feeding system, tablet pressing system, crushing system, whole grain system, screening system, hydraulic system, closed working bin, gas system (including vacuum degassing), cooling water system and electric control operation system.

The machine is a double support horizontal structure, two-stage feeding, designed to separate the processing area from the power transmission area, with good sealing performance and clean appearance, realizing the clean closed production from powder to particle. The parts in contact with materials (working chamber) and appearance are mostly made of high-quality stainless steel. The internal part is smooth and not easy to store materials, and the external part is smooth and easy to clean. The working chamber is airtight and independent, with multi-layer sealing and gas sealing to ensure the cleanliness requirements.

The layout of the whole machine is neat, compact and centralized. Clean appearance, easy disassembly and cleaning, realize the clean closed production from powder to particle. Table layout is neat, compact, centralized operation, safe, reliable, fast man-machine interface, and large amount of information. The equipment runs smoothly, and the noise 1.0 meters away from the equipment is below 80 dB. The equipment has risk identification and safety protection device.

The operation screen has good sealing performance, which can effectively prevent dust and splash. It is designed with degassing pressure display and adjustment function, as well as key switch, emergency stop and other functions. It can be operated through the touch screen when emergency stop and power cut-off are needed.