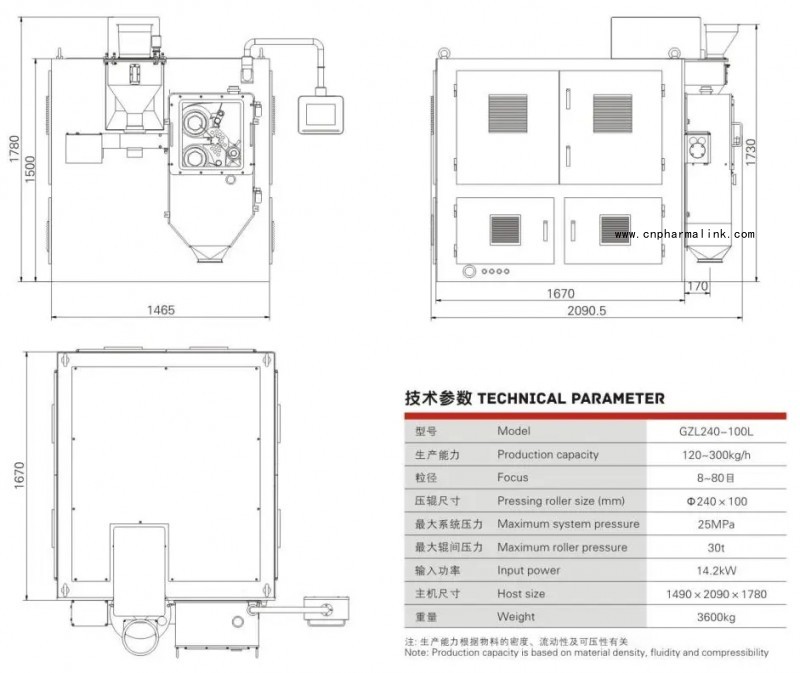

GZL240 Dry Granulator

Short Description:

The machine adopts two-stage screw feeding system.horizontal twin-screw feeding and unique cantilever design,which improves the range of processing materials and thesuccess rate and yield of granulation.

Application

Dry granulation is widely used in pharmaceutical,food,chemicaland other industries.It is especially suitable for granulation ofdrugs that are easily decomposed by moisture,easy to absorbmoisture,sensitive to heat,and the particles can be used fordensification to improve fluidity,tablet compression,Fillingcapsules and granules for bagging.Based on many advantages,it is widely used in various industries.

Feature

The use of liquid crystal touch screen and a variety ofautomatic control technology to improve the flexibility andsecurity of the device;

The movable zone is separated from the working zone toachieve clean and closed production from powder to granules.and the production effect prevents dust and cross-contamination,and all contact parts with materials are easilydisassembled and cleaned;

The whole machine is made of high quality stainless steel andthe contact material is 316.Full compliance with GMPrequirements for pharmaceutical production.

The water-cooled pressure roller has a built-in structure forthe inlet and outlet,and the test material does not heat upduring the extrusion process,which affects the materialproperties.

Structure Description

The horizontal layout of the whole set of production equipment meets the requirements of production process, and at the same time, the height requirements of the workshop are relaxed. Moreover, it makes it more convenient for the operator to disassemble, clean or adjust, at the same time, it also avoids the possibility of danger due to height, and increases the safety factor during disassembly, cleaning or adjustment.

The operation screen has good sealing performance, which can effectively prevent dust and splash. It is designed with degassing pressure display and adjustment function, as well as key switch, emergency stop and other functions. It can be operated through the touch screen when emergency stop and power cut-off are needed.

The contact part and appearance of the whole machine with the drug are made of high-quality stainless steel 316L (except for mechanical strength parts). The internal structure is polished without dead angle, and it is not easy to store materials. The external structure is simple, smooth and easy to clean. Other materials must be guaranteed not to fall off, impermeable, corrosion-resistant, disinfection resistant and easy to clean. The pipeline material is 304 stainless steel.

All parts in contact with drugs (working cavity) are sealed and independent, and the seals are composed of two or more levels to ensure cleanliness requirements and prevent pollution. The material meets the food grade requirements, and the material certificate shall be provided.