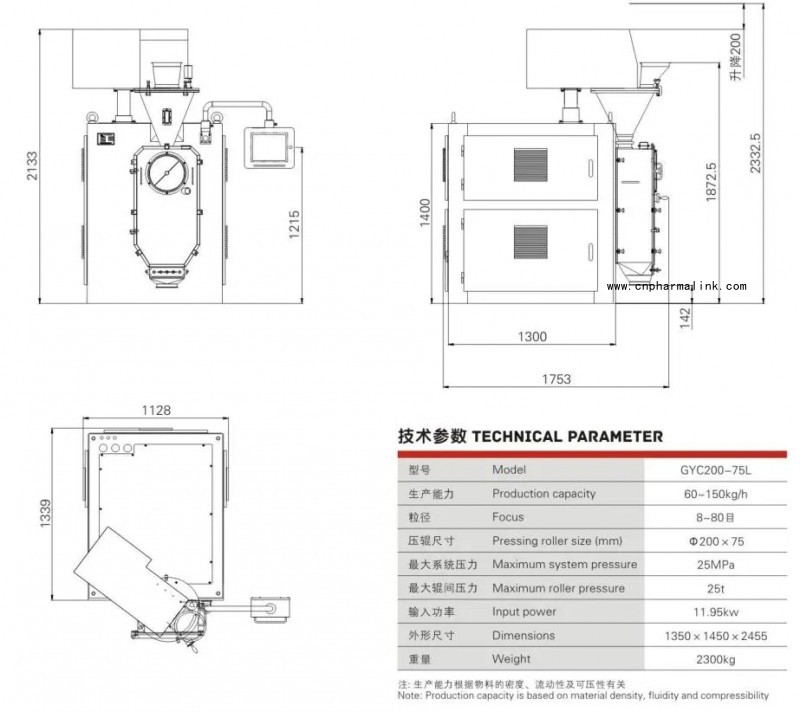

GYC200 Dry Granulator

Short Description:

The equipment pressure roller is horizontally arranged by acantilever structure,and the overall structure is simple andconcise.which is convenient for disassembly and cleaning.

Application

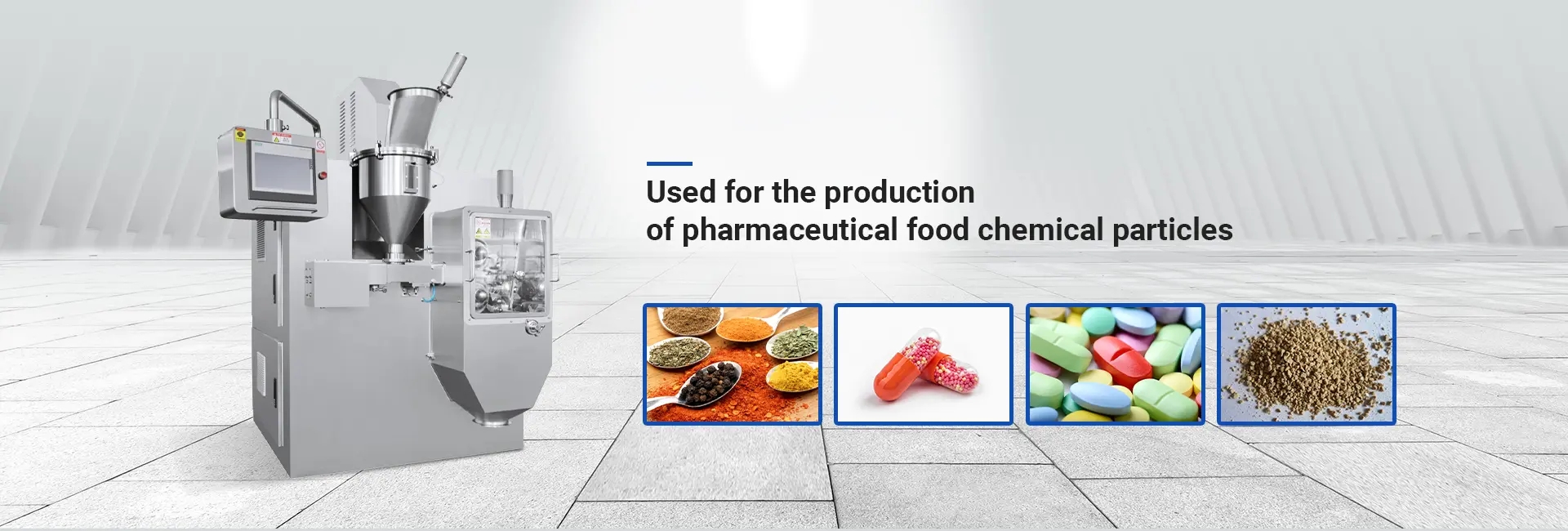

Dry granulator is widely used in pharmaceutical,biological,food.chemical and other industries.It is especially suitable forgranulation of materials that are easy to decompose whenexposed to heat,easy to absorb moisture,and sensitive to heatIt can be used to improve material flow,increase materialdensity and other effects.In the pharmaceutical field,itsparticles are mostly used in tablet wafers,filled capsules.andgranules.In addition,the dry granulator has the characteristicsof simple process,compact structure,high degree ofautomation,convenient use and maintenance,low noise andgood versatility.Based on many advantages,it is widely used invarious industries.

Feature

The equipment pressure roller is horizontally arranged by acantilever structure,and the overall structure is simple andconcise.which is convenient for disassembly and cleaning.With LCD touch screen and a variety of automatic controltechnology,the operation is simple,and the productiontechnical parameters are intuitive and easy to find and record.The whole machine is made of high quality stainless steel.and the contact material is made of 316 material.Fullycompliant with GMP requirements.The pressure roller is specially treated with special stainlesssteel,and its surface has high hardness,wear resistance andgood corrosion resistance.The pressure roller can control the temperature of the surfaceof the pressure roller through the cooling water to prevent thematerial from being deteriorated and bonded due to heatduring the extrusion process.

Structure Characteristics

1. the main machine is composed of the following parts: overall frame, vacuum feeding system (auxiliary machine), vertical feeding system, tablet pressing system, crushing system, whole grain system, screening system (auxiliary machine), hydraulic system, closed working bin, air system, cooling water system (auxiliary machine) and electric control operation system.

The cantilever design of the whole machine completely separates the processing area from the power transmission area, with clean appearance, easy disassembly and cleaning, and realizes the clean closed production from powder to particle. Table layout is neat, compact, centralized operation, safe, reliable, fast man-machine interface, and large amount of information. Safety signs and equipment nameplates shall be pasted at prominent positions of the equipment.

The horizontal layout of the whole set of production equipment meets the requirements of production process, and at the same time, the height requirements of the workshop are relaxed. Moreover, it makes the operator more convenient and thorough in disassembly, cleaning or adjustment, at the same time, it also avoids the possibility of danger due to height, and increases the safety factor in disassembly, cleaning or adjustment.

2. the contact parts and appearance of the whole machine with drugs are made of high-quality stainless steel 316 (except for mechanical strength parts). The internal structure is polished without dead angle, and it is not easy to store materials. The external structure is simple, smooth and easy to clean. Other materials must be guaranteed not to fall off, impermeable, corrosion-resistant, disinfection resistant and easy to clean. The pipeline material is 304 stainless steel.

3. all parts in contact with drugs (working cavity) are sealed and independent, and the seals are composed of two or more levels to ensure cleanliness requirements and prevent pollution. The sealing material shall be silicone rubber or PTFE, and the qualified inspection certificate and verification certificate documents shall be provided.

4. the whole set of system structure design is reasonable, each process in the process flow, production capacity match, no blocking, aggregate phenomenon, reliable operation.

5. metric units shall be used for measuring instruments and connectors of equipment, and qualified inspection certificate and verification certificate shall be provided; The installation and wiring of electrical appliances meet the electrical technical specifications and requirements;