Fixed Material Lifting Machine

Short Description:

The machine is a new machine researched and developedsuccessfuly by our company according to China's actual conditionsafter absorbing and digesting internationally advanced technology.thas such features as reasonable structure,stable performance.

Application

The machine is mainly used for conveying and charging solidmaterials in the pharmaceutical industry.It can work with themixer,tablet press,capsule filler,etc.It is also widely used insuch industries as medicine,chemical industry,food,etc.

Usage

YTG Series lifting charging machine is a new equipment developed by this company to meet the need of vertical lifting of material in the modern pharmaceutical process. It can be used as a lifting and charging equipment for various tablet compressing machines, capsule filling machines, mixing machines and tablet counting machines, there are many types of machines in JT Series for users to select and use, such as fixed lifting type, mobile lifting type, and mobile lifting turnover type.

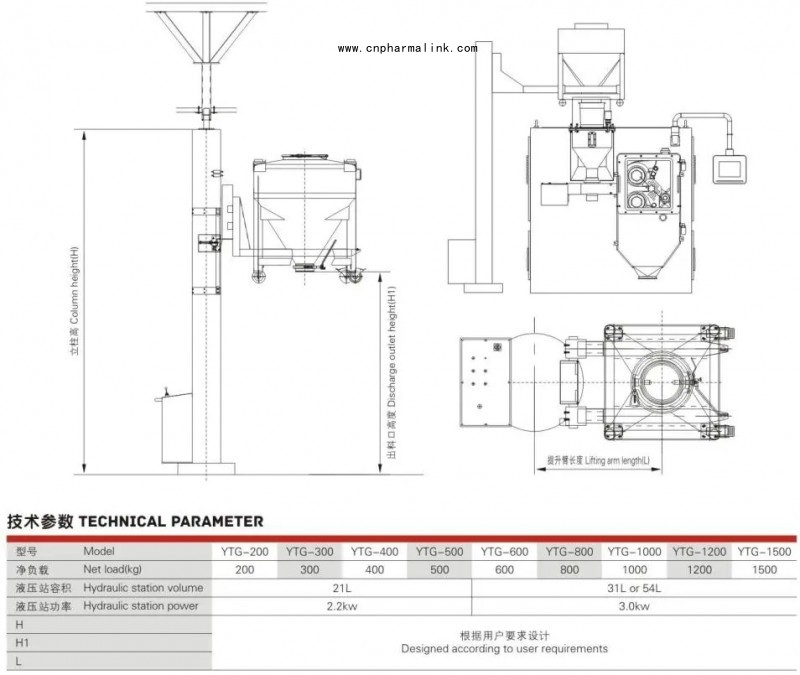

Working Principle

Push the hopper into the lifting arm which will lift or lower under electrical and hydraulic control, thereby carrying out the lifting, transfer and charge of material.

Principle

The machine is mainly composed of chassis,column,Iifting system.etc.When it works,push the hopper loaded with materials into thelifting crotch of the hopper lifter.Press the lifting button and thehopper will make lifting movement.After the hopper reaches thedesignated position,rotate the chassis to realize closed connectionwith the charging equipment.Start the discharging butterfly valve totransfer the materials to the next procedure.

Feature

The machine is a new machine researched and developedsuccessfuly by our company according to China’s actual conditionsafter absorbing and digesting internationally advanced technology.thas such features as reasonable structure,stable performance.convenient operation,no dead corners,and no exposed bolts.Themachine is easy to clean,effectively controls dust pollution andcross contamination,optimizes production processes,and fulymeets GMP requirements for medicine production.

● A high-tech equipment that integrates machinery, electronics and hydraulics into one body, with compact design and runs stably and reliably.

● The barrel body is made of quality stainless steel which is highly polished on inner and outer surfaces, without dead corner and conforms to the requirement of GMP.

● The fixed lifting type column frame can turn in a certain angle; the mobile lifting type can be freely moved in the working place, and the movement is convenient and flexible; the mobile lifting turnover type can be designed and manufactured to have a lifting charging arm that fits to the user’s original material barrel, so that the charging arm can tightly clamp, lift the barrel and can make 180°turnover.

● The material barrel can be used as a batching and storage barrel in the upstream procedure and as a charging hopper in the downstream procedure (compressing, filling and counting).

● The medicine is transported in a tightly closed state, thus avoiding contamination during transportation.

● The patented discharge valve is compact, convenient to discharge and easy to clean.

● It has thoroughly changed the traditional mode of manual operation, reduced the labor intensity, and the tightly closed production has avoided flying upward of dust and cross contamination during transportation. It fully conforms to the requirement of GMP.

● During the process of charging, there is no phenomenon of layering of material.