Dust Free Feeding Station

Short Description:

Dust-free operation,full-closed bag feeding and pipelinetransportation.

Overview

When the small bag material needs to be unbagged and poured into the next process, it only needs to be unpacked manually directlyl, When put into the system, the material dust produced during feeding is collected by the dust collecting fan. Material passes through safety screenl, The net can intercept large materials and foreign bodies, so as to ensure that the particles meet the requirements of discharge. The system is suitable for pharmaceutical, Small and medium-sized bags in chemical and food industries are put into, screened and unloaded, especially for materials with poor mobilityl, The feeding and screening, unpacking due to the role of dust collecting fan, can avoid the material dust everywhere flying.

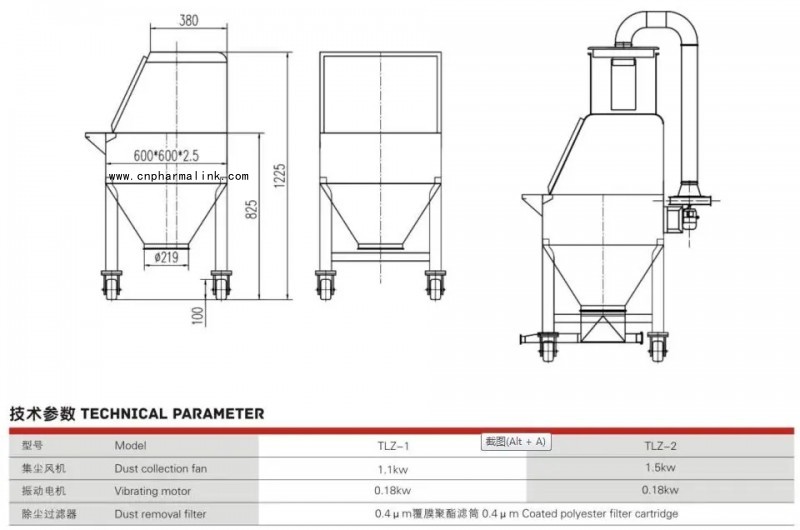

Equipment Structure

By the manual discharge bin, anti-pressure type feeding platform, under the bin, safety screen, filtration system, Dust collection system, back blowing system and other components. (Can be customized according to customer requirements).

Equipment Description

The use of dust removal and filtration type feeding operation platform can achieve manual feeding process without dust spill, After unpacking the material into the feeding table inside the cone, overflowing dust in the process of filling by strong negative pressure

The air flow is adsorbed, and then blocked by the filter element, and the clean gas is discharged through the fan inside the filter element;

In the working process of the system, the adsorption of the filter element to the material will lead to the increase of filtration resistance, so it needs to be adopted, The high flow pulse injection pressure is used to reverse blow the filter element, which needs to be manually pulled after a period of working time, Hand pull valve for back blowing (to the right for back blowing, neutral in the middle, to the left is closed) to reduce or clear, In addition to the material adsorbed on the surface, the running resistance of the fan is kept within the allowable range.

Application

The system is suitable for pharmaceutical,fine chemical,foodindustry,medium and small bag materials,screening andunloading.It is especially suitable for the feeding and screeningof materials with poor fluidity.

Principle

The operator places the bag on the stand and pushes itinto the grid.Then,the dither bag is dumped to make it empty,and the materialcan be intercepted by the safety screen to block large materials andforeign objects.The filtered material falls into the hopper by gravity.and can be connected to the conveying unit equipment through theconveving pipe at the bottom to effectively output the material tothe designated position.The built-in air-collecting dust filter cancolect dust from the dust produced during the emptying of the bagThe fiter is cleaned by reverse compressed air injection,and thecleaned dust falls back into the hopper for continuous uninterruptedfeeding.

Feature

Simple structure,safe and convenient operation,easy to maintain:

Dust-free operation,full-closed bag feeding and pipelinetransportation;

No dead angle design,easy to clean;

Automatic dust collection system to prevent dust from flying andimprove working environment;

Various specifications of the bag opening station can meetdifferent processing requirements;

Applicable to all industries involving pharmaceuticals,food.chemicals,batteries,etc.