ZL Granulator

Short Description:

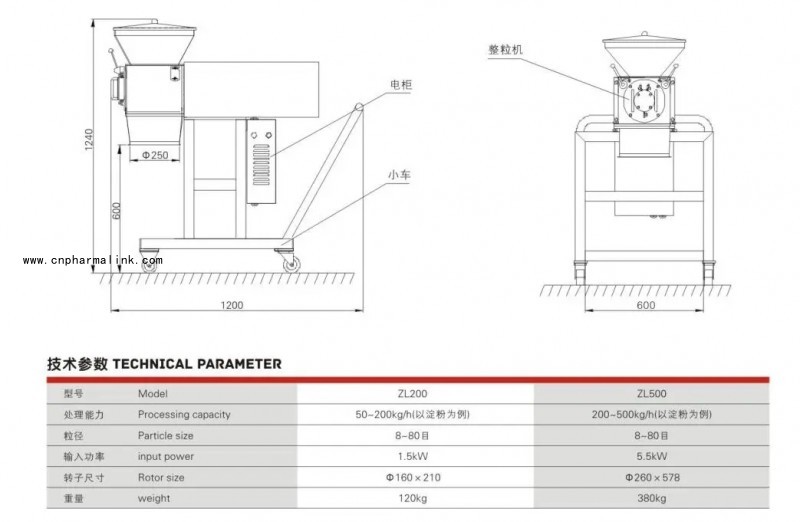

This machine is a movable whole grain trolley.

Material into the granulator, the whole machine blade relative motion with the orifice, the blade material extrusion on the orifice plate, through a combination of extrusion pressure and shearing force, to sheet or block material rolling into different sizes of particles, particles can be easily through the sieve plate granulator, not broken, larger particles within the pelleting machine continue to be crushed into small particles. Finish the rounded corners of the required number of grids here. This equipment can be used in conjunction with the dry granulator, can also be used to deal with the agglomerated material or the larger crystalline shape of the material, so that these materials into fine particles of material.

Application

The equipment will be agglomerated,agglomerated,and slicedinto granules to form irregularly shaped particles having a certainparticle size distribution and density requirements.Can be usedin the pharmaceutical,food,chemical and other industries.

Principle

After the material enters the granulator,under the extrusion of thewhole knives,the small particles can easily pass through the sieveplate of the granulator,no longer breakage,and the large particlescontinue to be crushed into small particles in the granulator.Herethe rounding work of the desired number of meshes is completed.

Feature

This machine is a movable whole grain trolley.

The powder particle forming process has less heat,less dust anduniform particles.The cars are all made of 304 stainless steel.Meet GMP requirements.

A dew-axis structure is used between the bearing and thechamber to prevent dust from entering the bearing and causingdamage.At the same time,it also prevents the oil seal of thebearing oil seal from entering the working chamber and causingmaterial pollution.

The rotor speed can be adjusted by 30-145r/min.

The distance from the lower discharge to the ground can be madeaccording to customer requirements and can meet customerrequirements.

The outlet of the whole granulator is in the form of a buckle foreasy cleaning and disassembly.

The frame type sieve plate makes it easy to replace the sieveplates of different specifications.