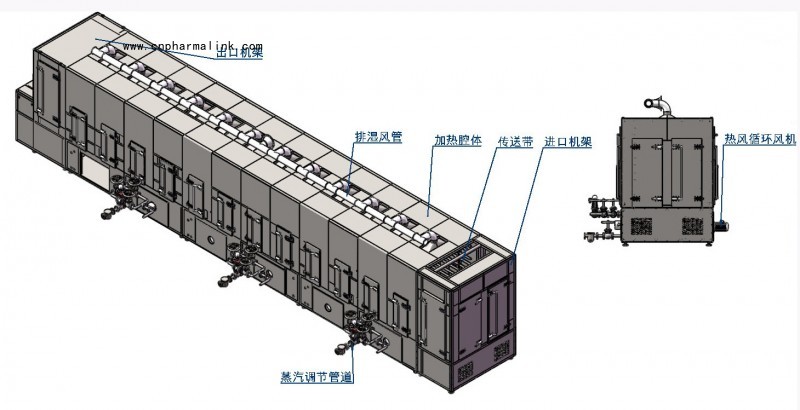

GDM belt dryer

Main purpose:

■The material is evenly laid on the Teflon mesh belt by the distributor (the traditional conveyor belt is stainless steel metal mesh belt. In the drying process, due to the rapid heat conduction of the metal, the material contact surface and non-contact surface are easy to form a positive and negative surface, making the material dry unevenly). It is dragged by the transmission device and moves in the drying chamber. The drying chamber is composed of several units (designed according to the production demand of customers), each unit has independent hot air circulation, and the moisture is discharged by the top moisture discharge pipe. The heat exchanger at the bottom of the heating chamber and the heat circulation fan are composed to convert the steam heat energy into hot air. The hot air is formed into internal circulation by the heat circulation fan. The hot air passes through the mesh belt full of materials from top to bottom to complete the process of heat and quality transfer and take away the moisture of materials. The mesh belt moves slowly, and the running speed can be adjusted freely according to the material temperature. The temperature of the chamber is detected by the temperature sensor, and the electromagnetic control valve on the steam pipe is adjusted to realize the automatic temperature control. The transmission speed, circulating fan frequency and temperature setting can be adjusted on the touch screen. It is mainly used for the continuous drying production of traditional Chinese medicine pills, granules and raw materials (roots, stems, leaves and strips).

Performance and characteristics:

■This series of dryer has the advantages of fast drying speed, high evaporation strength and good product quality.

■The drying temperature, circulating fan frequency, transmission speed and frequency parameters of the exhaust fan can be adjusted and set according to the process. Parameter setting can be saved, and different parameter settings can be called according to the process.

■The equipment is suitable for connecting with front and rear equipment to realize efficient linkage production.

Product structure:

■The equipment is mainly composed of feed frame, heating box, discharge frame, transmission part, heat exchanger, circulating fan and steam control part.