Brief introduction

On the basis of advanced European technology, this YBG300 full-servo 3D wrapping machine is developed. The machine is widely applied for the continuous packing for boxes in pharmaceutical plants.

The machine

The machine can be used for the membrane wrapping for a single box, or many boxes, sixes sides can be covered completely, and the horizontal envelop-type folding is adopted.

In this machine, the thermal-shrinkage film can be used, including PVC or BOPP, etc.

Features

This full-servo machine is driven by six servo motors, and there are advantages of precise control, stable run and the one-key resetting.

The modular design is adopted, and all dies can be replaced within five minutes.

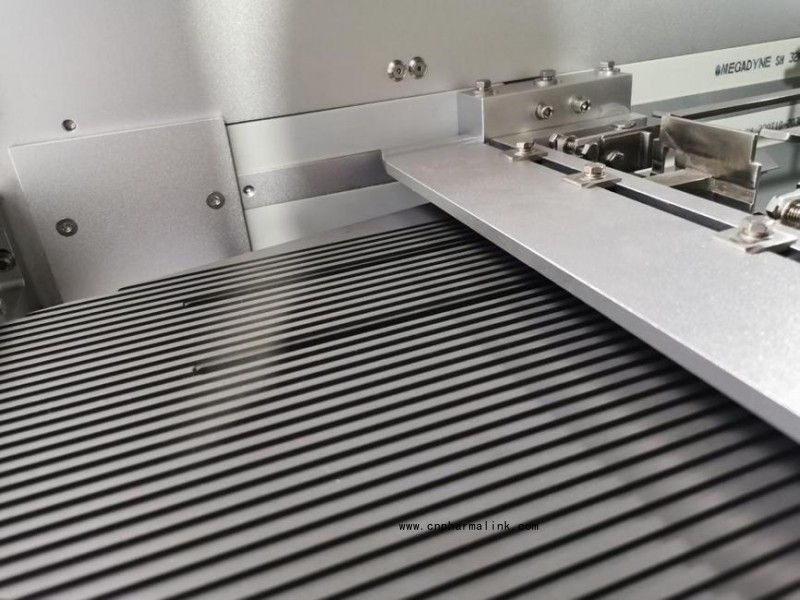

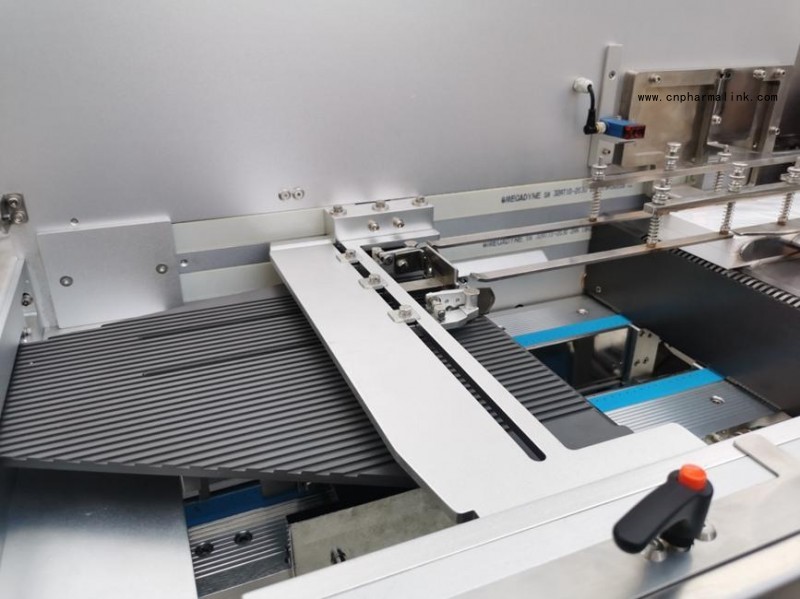

With the balcony-type structure, it is convenient to operate and clean, which meets the GMP standard.

After the packing, the membrane is cut, and there is the vacuum static electricity removing for the package.

When the box size is changed, the packing parameters can be regulated in the HMI.

Some formulas can be saved, and it is convenient to be read and be applied.

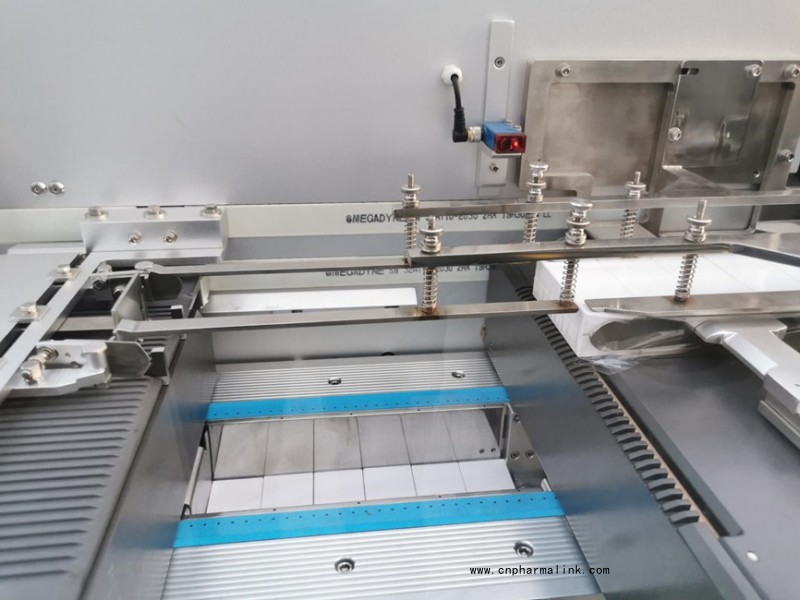

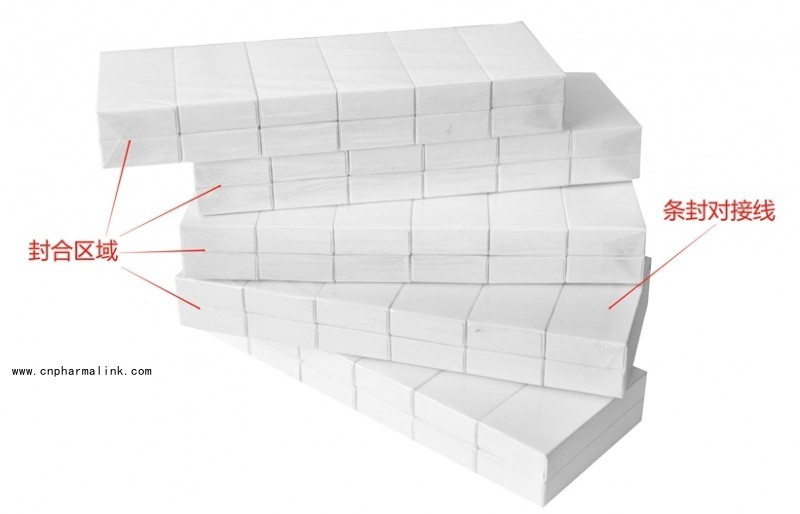

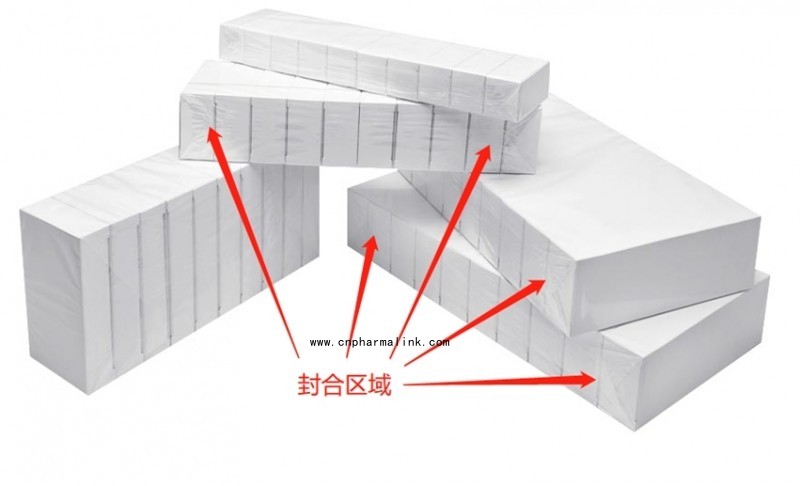

With the continuous thermal-sealing design, both sides of the package can be heated evenly, and the sealing effect is good. After the sealing, packages are conveyed out directly.

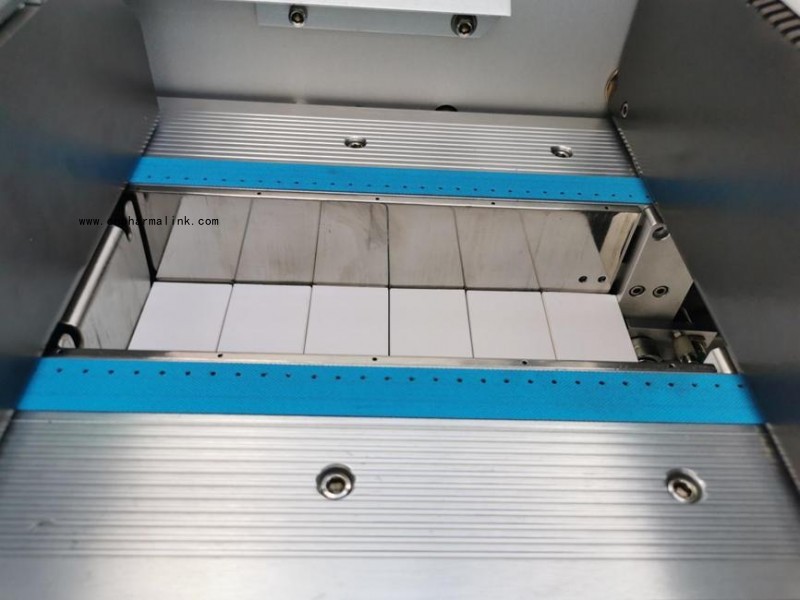

The machine can be used for the membrane wrapping for many kinds of boxes stacking, for example: 1×10 or 2×5, etc.

The machine can be connected in a production line.

Functions

Monitoring

For the membrane roll, when the membrane gets to its low limit, the machine will be stopped automatically.

For the vacuum membrane conveying belt, there is a sensor, when the membrane gets to a desired position, the belt is stopped.

There is a sensor for boxes, which is used to detect whether the box has get to its position.

The stacking height of boxes can be detected.

The temperature of the thermal resistance in the heating station is PID controlled.

The safety door is equipped, and once the door is opened, the machine will be stopped automatically.

There are alarm indicators (red, orange and green).

Electric parts

Protecting class: IP54

Controller: EtherCAT bus and I/O module.

Sensors & solenoid valves: Quick mounting is adopted.

The machine is controlled by the controller (Delta, IEC61131-3), there is the digital servo amplifier, and those signals from the I/O modules and actuators can be received.

With the PLC control system and the shifting register, reliable operation can be ensured.

The state and configurations of the shifting register can be read in the screen.

Even there is a sudden power off, the PLC data will not be lost. After the power is reset, the machine needs to be reset by manual, and those pre-loaded format will be loaded again.

Operation interface

10” true-color touch screen. Can be connected with the printer. TCP/ IP protocol. USD interface. IP54.

With graphic user interface, it is convenient to input parameters in the HMI, and it is easy to operate.

System records and errors can be checked and traced.

There is the account managing system, in which the user name and the password needs to be input.

Languages: English/ Chinese

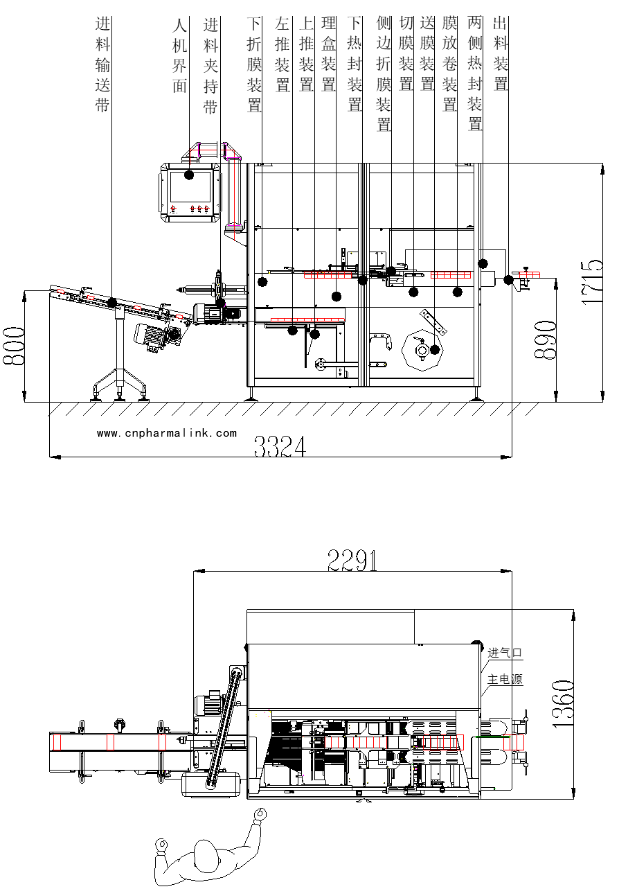

Technical specifications

|

S.N. |

Items |

Specifications |

|

1 |

Packing speed |

35 ~ 60packages/min (It is decided by the box size and the stacking method.) |

|

2 |

Box length |

30 ~ 300mm |

|

3 |

Box width |

60 ~ 250mm |

|

4 |

Box height |

15 ~ 150mm |

|

5 |

Membrane |

BOPP or PVC |

|

6 |

Outlet height |

890±30, mm |

|

7 |

Total power |

10Kw |

|

8 |

Voltage |

380V/ 50Hz |

|

9 |

Rated gas exhausting pressure |

0.6Mpa |

|

10 |

Air flow |

20L/min |

|

11 |

Noise |

Not more than 75dB |

|

12 |

Machine weight |

1450Kg |

|

13 |

Machine size |

(1000(Conveying)+2350(Packing machine)) ×1550×1700, mm |

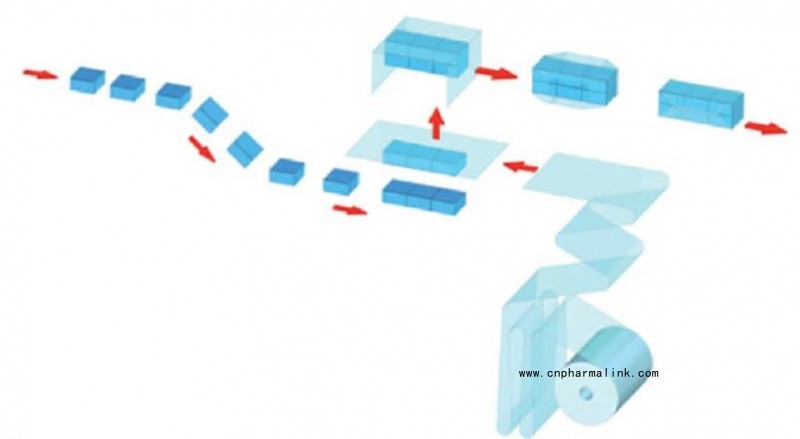

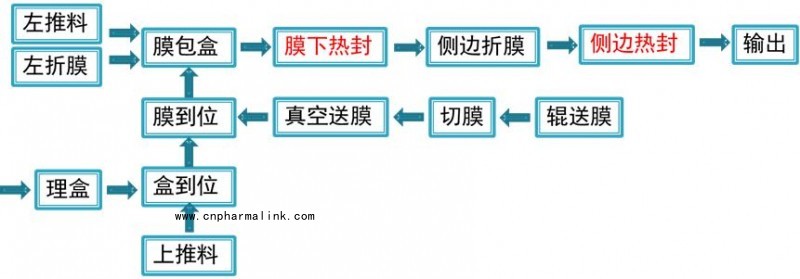

Work flow

Configurations

|

S.N. |

Name |

Q’ty |

Unit |

Brand |

|

1 |

Touch screen |

1 |

set |

Delta, Taiwan |

|

2 |

CPU |

1 |

pc |

Delta, Taiwan |

|

3 |

Servo driver |

6 |

set |

Delta, Taiwan |

|

4 |

Servo motor |

6 |

set |

Delta, Taiwan |

|

5 |

V20 VFD |

3 |

set |

Delta, Taiwan |

|

6 |

Interchanger |

1 |

set |

Delta, Taiwan |

|

7 |

Module & Network cable |

1 |

set |

Delta, Taiwan |

|

8 |

Vacuum pump |

1 |

set |

BECKER, Germany |

|

9 |

Photoelectric sensor |

1 |

set |

Leuze, Germany |

|

10 |

Photoelectric sensor for the protecting |

2 |

set |

Leuze, Germany |

|

11 |

Photoelectric sensor for the position |

2 |

set |

Sick, Germany |

|

12 |

Photoelectric sensor for the blocking |

1 |

set |

Leuze, Germany |

|

13 |

Proximity switch |

5 |

set |

Leuze, Germany |

|

14 |

Photoelectric sensor for membrane |

1 |

set |

Sick, Germany |

|

15 |

Safety door lock |

2 |

set |

Schneider |

|

16 |

Thin cylinder & Mini cylinder |

2 |

set |

SMC, Japan |

|

17 |

Balancing cylinder |

1 |

set |

SMC, Japan |

|

18 |

5-way valve |

3 |

set |

SMC, Japan |

|

19 |

Solenoid valve& Residual-pressure valve |

1 |

set |

SMC, Japan |

|

20 |

AHU & Air-pressure meter |

1 |

set |

SMC, Japan |

|

21 |

Triplet part |

2 |

set |

SMC, Japan |

|

22 |

Digital locator |

4 |

set |

Elesa+Ganter, Germany |

|

23 |

Locking handle |

6 |

set |

Elesa+Ganter, Germany |

Servo controlling spots

|

Membrane feeding |

Cutter |

Vacuum membrane feeder |

Left membrane folding |

Left pushing |

Upper pushing |

|

1 |

1 |

1 |

1 |

1 |

1 |

Variable-frequency speed regulating spots

|

Conveying belt |

Left/ right turnover conveying belt |

Side heat-sealing belt |

|

1 |

1 |

1 |

Details:

When this conveyor is equipped, the machine can be connected with the cartonning machine or the weighing machine, and the linkage photoelectric signals are equipped.

Two times of conveying are driven by one VFD, so the conveying speed at both sides are same. And the position of the servo upper pusher can be regulated in the touch screen.

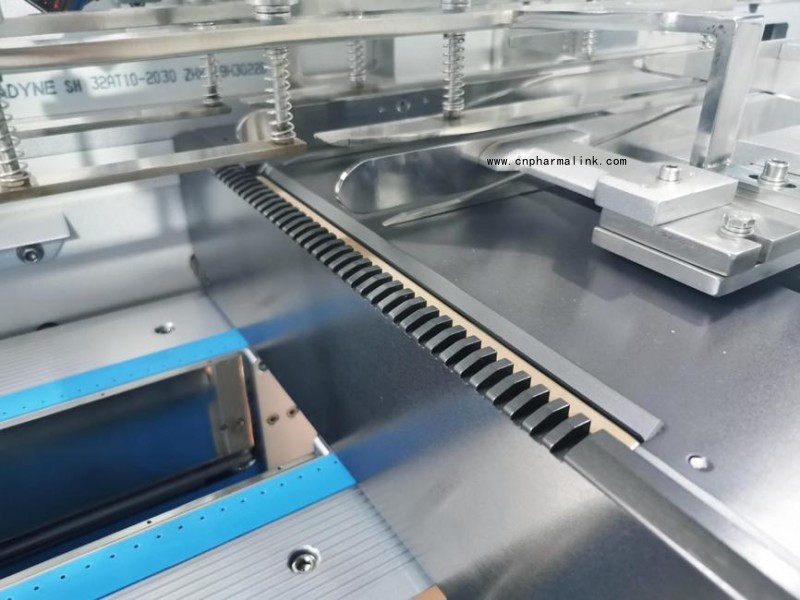

The membrane-folding pusher and the boxes pusher are driven by their respective servo, and the pushing speed is fast. With the ruler and the origin-position memory, it is convenient to regulate.

The vacuum membrane adsorbing is used, and the adsorbing ability is strong. The conveying length is controlled by the servo, and the conveying position is accurate. The conveying length can be set in the HMI.

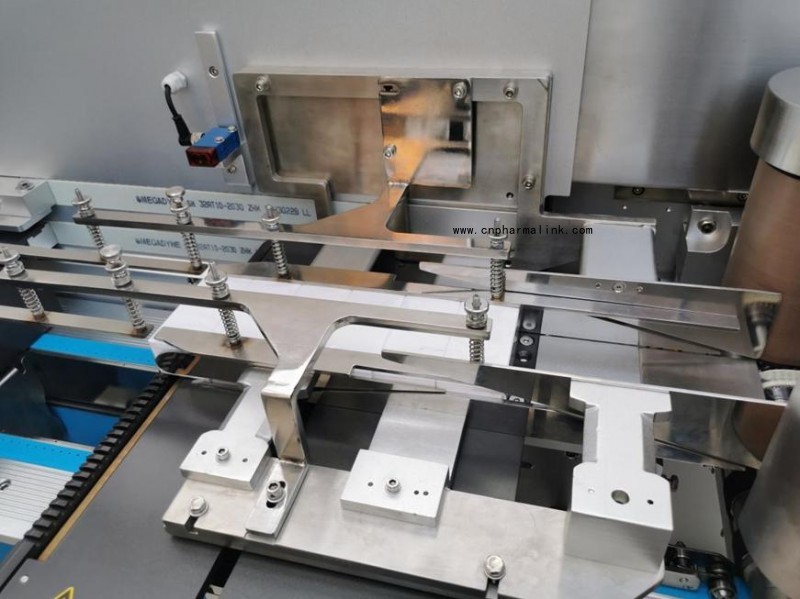

For the horizontal sealing board, the heating pipe is used, and with the PID control and the constant-temperature control, the sealing effect is good.

Dies for the side membrane folding is positioned by the pin, and it is convenient to replace.

Diameter of this membrane roll: Max. 300mm

When there is lack of membrane, the machine will alarm. And if the membrane is run out, the machine will be stopped.

The membrane feeding and the cutting is controlled by their independent servo, and the cutting length can be set in the HMI.

With the heating belt, the side heating is even.

Sample 1

Size: 108×48×19(mm). 2×6=12boxes.

Sample 2:

Size: 108×56×22(mm). 1×10=12boxes.

Schematic diagram: