This machine is widely used in pharmaceutical. Chemical, food and other industries. The wet powder material can be made into granules, and the dry material can be crushed into blocks, and the granules can be quickly completed. This machine is a kind of wet powder mixture, under the action of positive and negative rotation of the rotating drum, forced through the screen and made into particles of special equipment. The equipment is a new type of equipment developed by our company recently, its advantage is automatic unloading, the efficiency of YK-160 swing granulator 2-3 times, and meet the GMP standard, is one of the ideal granulator. Simple structure, easy to operate, easy to move. Automatic unloading, make up for the old product manual unloading shortcomings. Continuous operation. It is suitable for semi-dry powder and sticky materials, Chinese medicine granule, food solid beverage, chicken essence, etc.

[Working principle] :

Through mechanical transmission to make grinding knife and pressing blade for opposite rotation, pressing blade into a certain Angle to press the material downward into the grinding knife, grinding knife on the large Angle spiral blade will push the material to the screen wall, and then through the blade, the material from the screen hole extruded into particles.

【 Structure features 】 :

The structure of hopper and pelleting device is designed according to the principle of installation, cleaning and easy to use. All components in contact with materials are made of stainless steel to ensure the cleanliness of products.

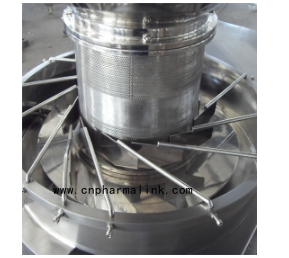

②: All parts of the particle manufacturing device are completely sealed to prevent lubricating oil from mixing into raw materials.

(3) : screen clamp tube is used to clamp the screen, to ensure that the screen close to the rotating drum is not loose.

(4) : users can according to the requirements of the product, choose the corresponding screen, manufacture of various specifications of particles.