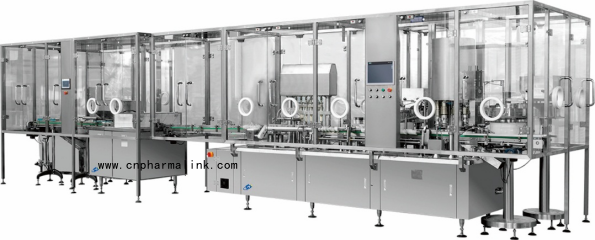

YGX-A Eye/ear drop filling and sealing production line

USD340,000.00

1 SET

90 DAYS

FOB/CNF

T/T or LC AT SIGHT

YGX-A Eye drop/Nasal drop filling, plugging and capping machine is designing and manufacturing after consulting from many world top quality equipment and their experience, also we improved for several years both in our own R&D department and our cooperated customers, and now it is become the reliable equipment which used for producing many kinds of eye drop and nasal drop etc. products, also with top quality component parts and beautiful design, the machine run very smoothly.

Ø The machine is made up of following working sections: linear bottle loading system, linear tracking type filling system, continuous mode tracking type plugging system, continuous mode tracking type capping system, main driving system, cam control gear system, electrical control system, etc.

Ø Linear bottle loading system: controlled by high precision cam control system, the bottles are conveyed to the main machine and waiting for filling, because all the driving system is in the control box, the working table is very cleaning and neatly without any pollution, and easy for changing the change parts.

Ø Linear tracking type filling system: the 6 filling nozzles are controlled by cam system, and during the filling working, the nozzles are directly inserting the bottles, filling meanwhile the nozzles will be lifted slowly, so that there will be without any drop spray outside the bottle, and without and dropping happen, also the machine has no bottle no filling and cap loading function.

Ø The machine is adopting 6 high quality ceramic piston pumps, and every pump is driving by servo control system independently, the filling volume can be easily set on the touch screen.

Ø Adopting the vacuum absorbing system to carry the plugs, and then plugging on the bottles through rotary tracking method, and the plugging working step is all well controlled by cam system, which is very smoothly and precisely running.

Ø The caps are automatically arranged and convey from the oscillator cap hopper, and then capping the bottles through rotary tracking type method, which is very stable, and it has with no plugging no capping function; the capping head up and down action is well controlled by cam system, which is very easy for disassemble when cleaning and improving; what’s more, there are 10 capping heads, and every capping head has over loading protecting system, when the capping system is up to some torque force which the caps are enough screwed, the capping head will be automatically slip, so that the caps will not be damaged during capping.

Ø The machine every working step and movements are all controlled by high precision cam system, and all the convey belt and disc is made of high-quality TEFLON material, which is not cracking and distortion.

Suitable bottles: 5-30ml

Working capacity: 150-180bottles/minute

Filling accuracy: ≤±1%

Capping qualify rate: ≥99%

Need compressed air pressure:0.4-0.6Mpa

Total power needed: 380V 50Hz 6KW

Design and manufacture of special-shaped bottle filling production line in eye drop/nasal drop industry, including bottle unscramble, bottle air washing, filling, plugging and capping, labeling, etc.