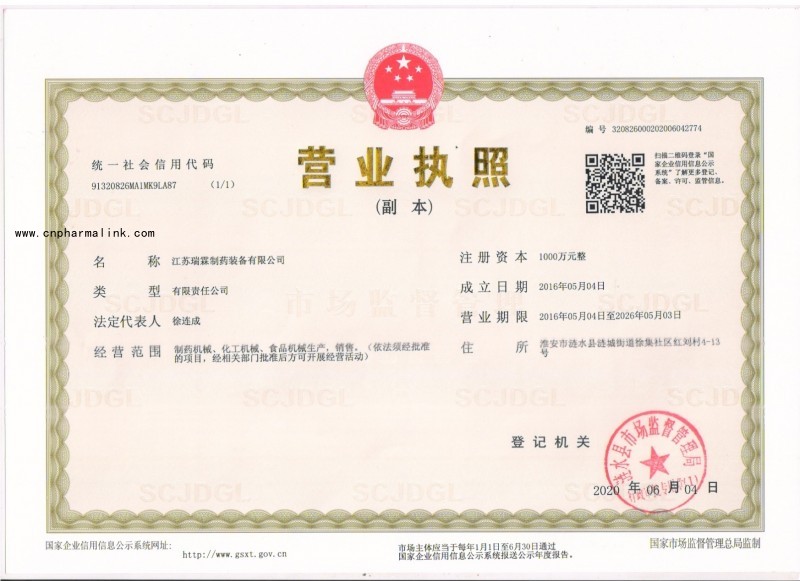

Jiangsu Ruilin Pharmaceutical Equipment Co., Ltd

Enterprise introduction

Jiangsu Ruilin Pharmaceutical Equipment Co.,Ltd. is a member of China Association for Pharmaceutical

Equipment. Founded in 2010, our company is located in Lian shui County, Jiangsu Province, enjoying beautiful scenery. Specialized in producing drying, mixing and

granulating equipment,our company is a comprehensive enterprise integrating professional design and manufacturing of solid preparation equip ent. By holding the enterprise development philosophy of "surviving by quality, developing through innovation and creating benefit with quality', our company has established good cooperation relationships with many enterprises such as Xiu zheng Pharmaceutical Group, Jilin Zi xin Group, Jilin Ya tai Group, Gui zhou Xin bang Pharmaceuticals, Ya bang Pharmaceutical Co.,Ltd., Dong bao Pharmaceutical Group,Changchun Lisheng Pharmaceutical Group, Zhejiang Zuo li Pharmaceuticals, Tong hua Zheng he Pharmaceuticals,Li zhu Group, Jiu zhi tang, Buchan g Pharmaceuticals, Tai ji Group, etc. We sincerely expect friends from all circles to visit us for business talk and cooperation and join hands with us to create brilliance together.

Excellent team management

The perfect system, highly efficient and strict operation system

are the solid foundation for sound management decision and

stable business development of our enterprise. Over the years,

the behavior standards and rules of employees are continuously

improving, and the enterprise management is moving towards a

scientific, standard and professional level. Now, our company has

a contingent of well-trained employees who can meet the needs

for modern enterprise management and production, laying a firm

foundation for future development of our company.

Production and equipment

Company has advanced processing equipment and strictly management system . All products are

inspected by high precision instrument . We also have professional technical team , provide technical support while machine developing and manufacturing .

We use professional people to do professional things, build professional enterprise brand image project, and better improve the popularity of enterprise brand and product sales.

Featured products

|

PRODUCT NAME

|

APPLICATION

|

|

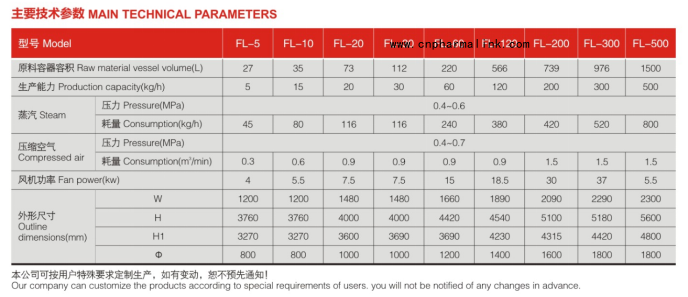

FLUID BED DRYING GRANULATOR

|

The machine is a widely used process equipment in pharmaceutical, food, chemical, dairy and other industries. It has the functions of mixing, granulation and drying.

|

|

PICTURE

|

PRINCIPLE

|

|

|

After the air is purified and heated, it is sucked from the lower part of the boiling granulation dryer by the induced draft fan and passes through the distribution plate of the material silo to make the material powder particles or wet particles in the boiling fluidization state in the raw material container. It is preheated and mixed by the purified heated air. During granulation, the adhesive solution is atomized and sprayed to make several particles aggregate into pellets containing adhesive, Due to the continuous drying of materials by hot air, the water in the pellets evaporates and the adhesive solidifies. This process is repeated to form ideal and uniform microporous spherical particles.

The boiling granulation method is the comprehensive application of spray technology and fluidization technology. It makes the traditional mixing, granulation and drying process complete in the same equipment at one time and realizes one step granulation.

|

|

FEATURES

|

|

◆The main machine adopts the most advanced design concept of Company. It improves material fluidity through powder granulating (mixing, granulating and drying)

◆The operation is carried out in a closed negative system.

◆The equipment is provided with the closed sampling function.

◆The air intake control valve adopts proportional adjustment.

◆The air intake heating system can adopt two heating modes such as electric heating or steam heating.

◆The machine s equipped with the advanced WIP cleaning system.

◆The machine meets the requirements for production in FDA/CGMP

◆The machine can be provided with 10Bar explosion-proof design according to user requirements.

|

|

PRODUCT NAME

|

APPLICATION

|

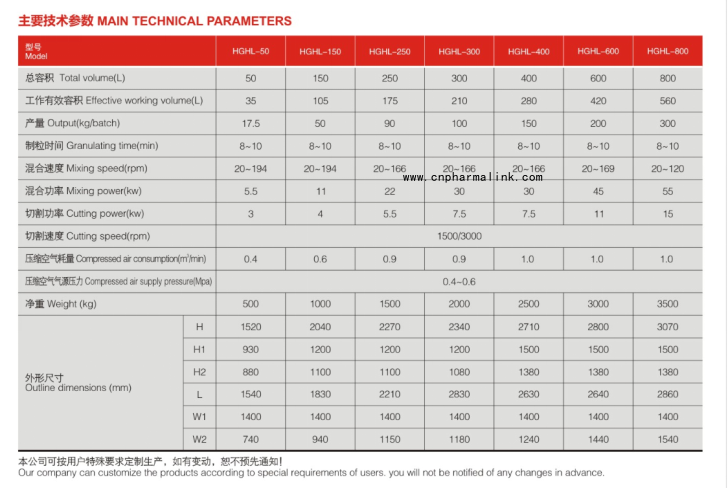

HIGH POSITION WET TYPE MIXING GRANULATOR

|

The machine is one of the commonly used process equipment in the production of solid preparations in the pharmaceutical industry. It has many functions such as mixing and granulation, and is widely used in pharmaceutical, food, chemical and other industries.

|

|

PICTURE

|

PRINCIPLE

|

|

|

The powdery materials are added to the mixing container through the batching system. First, they are rotated and pushed by the bottom mixing paddle to make fluidization movement and fully mixed. Then, the adhesive is injected through the pressure gun to turn the dry powder into wet soft materials. At the same time, they are made into uniform wet particles under the dual action of the mixing paddle and the side wall high-speed cutter.

|

|

FEATURES

|

|

◆The whole machine is made of high quality stainless steel;

◆It is provided with special mixing barrel and conical column of a compound structure The caners on the inner wall are subjected to smooth transition and mirror polishing with easy cleaning and without material sticking;

◆The mixing and granulating procedure can be completed in one step with the materials in the closed mixing barrel;

◆PLC control, variable frequency speed regulation of mixing and granulation motor, and all environmental actions are automatic and automatic;

◆Equipped with interlocking protection device, the operation is safer;

◆Equipped with printer, it can automatically print all process parameters, and the original records are consistent with the actual situation;

◆It can be equipped with wet granulator and swing granulator, which are connected with boiling dryer to form a fully closed granulation production line.

|

|

PRODUCT NAME

|

APPLICATION

|

|

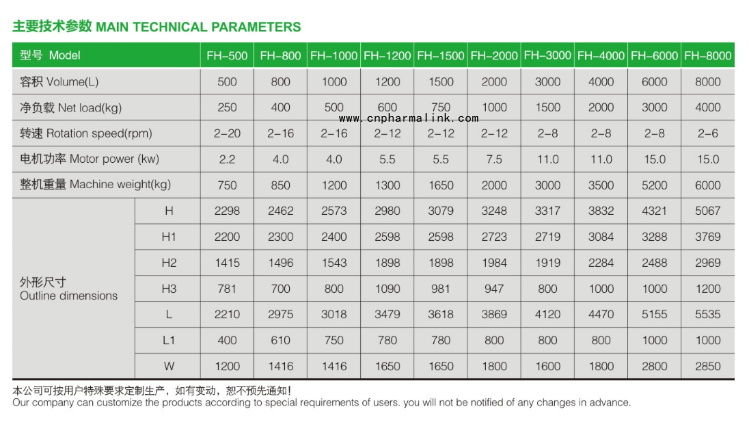

SQUARE CONE MIXER

|

Square cone mixer is a kind of mixer developed by combining the characteristics of a variety of mixers, which is widely applicable. It can fully ensure compliance with national drug GMP and other relevant industry standards. It is especially suitable for the mixing process of products with relatively single variety and large batch. Such as the mixing of solid preparations in medicine, food, dairy products, chemical reagents and other industries.

|

|

PICTURE

|

PRINCIPLE

|

|

|

The materials enter the mixing barrel through manual feeding, vacuum feeding, floor material dropping or special lifting machine.

As the symmetrical axis of the hopper forms an included angle with the rotation axis, different components of materials will make three-dimensional movement in the closed hopper, producing strong turning, diffusing and shrinking actions and achieving the best mixing effect.

|

|

FEATURES

|

|

With novel design, compact structure and beautiful appearance, the machine can reach mixing evenness of 99% and volume loading coefficient of 0.8. It has such features as high rotation height, stable running reliable performance and convenient operation. The inner and outer walls of the barrel are subjected to mirror polishing with easy discharging and easy cleaning and without any dead comers and cross contamination, meeting GMP requirements.

|

|

PRODUCT NAME

|

APPLICATION

|

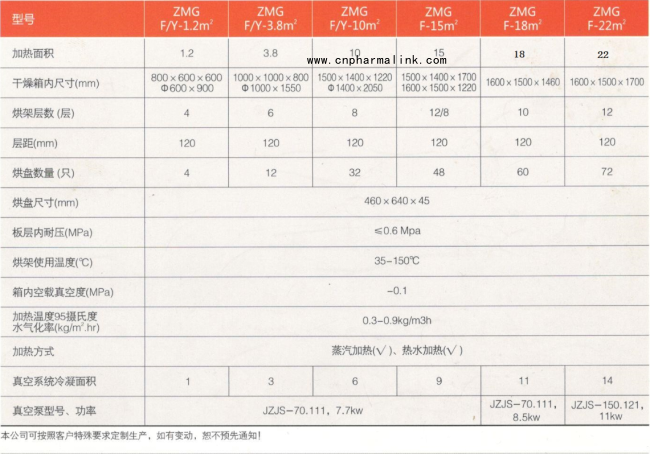

AUTOMATIC PULSATING VACUUM DRYER

|

This equipment is suitable for drying most materials at present, such as traditional Chinese medicine extract, traditional Chinese medicine, raw material powder, heat sensitive materials, etc. It is especially suitable for drying traditional Chinese medicine extract.

It can be widely used in pharmaceutical, chemical, food, electronics and other industries.

|

|

PICTURE

|

PRINCIPLE

|

|

|

This type of equipment uses the principle that the gasification temperature of water under negative pressure will be reduced. Therefore, it has the characteristics of low temperature, fast and clean; The gasification rate of liquid increases with the decrease of atmospheric pressure, which greatly improves the evaporation of water. Aiming at the problems of uneven contact of heating surface, carbonization of contact surface and surface scaling in the original vacuum drying oven, the equipment is developed. Greatly improve the heating surface of the equipment, improve the evaporation and discharge speed of water, and improve the vacuum degree of the equipment during use.

|

|

Features

|

|

◆ hot water heating, high drying efficiency, uniform heating, no gelatinization (advantages of plate layer);

◆ laminar flow vacuum design promotes the rapid discharge of water and improves the drying efficiency;

◆ controllable and adjustable vacuum degree, rapid bubble breaking, fast water evaporation, no overflow and material loss (bubble breaking advantage);

◆ it can be designed as full CP design (no dead angle design for internal arc);

◆ controllable and adjustable material temperature and online display to reduce material loss (temperature control);

◆ the automatic control mode can select a variety of drying modes (high speed, standard, low speed), and can use the drying and process requirements of a variety of materials (control system);

◆ it has one key operation mode to ensure the repeatability of material drying stage, and has printing function to facilitate internal process management and equipment verification (control system).

|

|